Compensation for professionals specializing in the maintenance and repair of aircraft engines and related systems is a critical factor for both job seekers and employers. It reflects the value placed on the highly specialized skills required to ensure the safe and efficient operation of aircraft. This figure typically encompasses base pay, potential bonuses, and benefits packages. For example, an individual with several years of experience working on jet engines for a major airline might command a higher salary than an entry-level technician in a smaller maintenance facility.

The financial remuneration attached to this role is significant due to the demanding nature of the work, the rigorous training involved, and the substantial responsibility inherent in ensuring flight safety. Historically, this compensation has remained competitive to attract and retain qualified personnel in an industry with stringent safety standards and a constant need for skilled labor. The capacity to maintain and troubleshoot intricate propulsion systems is indispensable, and accordingly, those who possess these skills are financially rewarded.

This article will examine several key elements that influence earnings in this field, including experience level, geographic location, employer type, and relevant certifications. Understanding these factors can provide valuable insight into potential career earnings and inform decisions regarding education, training, and job selection. Furthermore, the impact of industry trends and technological advancements on compensation will be addressed.

This section provides practical guidance for maximizing earnings and career potential within the aerospace propulsion maintenance field. Strategic planning and continuous professional development are crucial for achieving long-term financial success.

Tip 1: Seek Advanced Certifications: Obtaining certifications beyond the basic FAA Airframe and Powerplant (A&P) license, such as specialized engine-specific certifications (e.g., Pratt & Whitney, Rolls-Royce), can significantly increase earning potential. Employers often prioritize candidates with demonstrable expertise in specific engine types.

Tip 2: Gain Experience with Diverse Engine Types: Exposure to a wide variety of engine models and manufacturers expands skill sets and increases marketability. Technicians proficient in multiple engine platforms are highly sought after.

Tip 3: Pursue Opportunities with Major Airlines: Large commercial airlines typically offer more competitive benefits packages and higher pay scales compared to smaller maintenance facilities or regional carriers. Competition for these positions is often intense, requiring a strong resume and proven track record.

Tip 4: Relocate to High-Demand Areas: Geographic location significantly impacts wages. Regions with a high concentration of aerospace manufacturing or maintenance facilities (e.g., Seattle, Dallas-Fort Worth) generally offer higher compensation due to increased demand for skilled technicians.

Tip 5: Consider Supervisory or Management Roles: Transitioning into supervisory or management positions (e.g., lead technician, maintenance supervisor) offers opportunities for increased responsibility and higher salaries. This often requires additional training in leadership and management principles.

Tip 6: Continuously Update Technical Skills: The aerospace industry is constantly evolving. Investing in ongoing training to stay current with the latest engine technologies and maintenance procedures is essential for career advancement and maintaining a competitive edge.

Tip 7: Network with Industry Professionals: Attending industry conferences and joining professional organizations (e.g., Aviation Technician Education Council) provides valuable networking opportunities and access to information about job openings and industry trends.

In summary, proactive career management, continuous learning, and strategic decision-making are key factors in optimizing earning potential within the aerospace propulsion technician field. By focusing on skill development, seeking out high-demand opportunities, and staying abreast of industry advancements, professionals can significantly enhance their long-term financial prospects.

The following sections will further explore specific factors that contribute to variations in compensation and provide a comprehensive overview of the industry outlook.

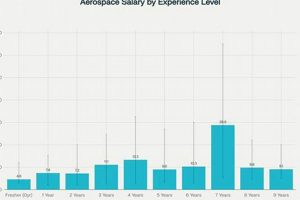

1. Experience Level

Experience level is a primary determinant of compensation for aerospace propulsion technicians. As proficiency and expertise grow through years of practical application, so does the potential for increased earnings, reflecting a greater ability to handle complex tasks and solve intricate problems.

- Entry-Level Positions (0-3 years)

Entry-level roles typically involve performing basic maintenance tasks under supervision. Technicians at this stage are focused on learning fundamental skills and gaining familiarity with various engine types and maintenance procedures. Consequently, compensation tends to be lower, reflecting the need for continued training and direct oversight. An example includes assisting senior technicians with routine inspections and component replacements.

- Mid-Level Positions (3-7 years)

Technicians with several years of experience can perform more complex maintenance and troubleshooting tasks independently. They have developed a solid understanding of engine systems and are capable of diagnosing and resolving a wider range of issues. This increased autonomy and skill set translate to higher earning potential. For example, mid-level technicians might be responsible for performing major engine overhauls or troubleshooting complex system malfunctions.

- Senior-Level Positions (7+ years)

Senior technicians possess extensive knowledge and experience, often specializing in specific engine types or maintenance procedures. They may take on leadership roles, mentoring junior technicians and overseeing complex projects. Their expertise is highly valued, resulting in significantly higher salaries. A senior technician could be responsible for leading a team during engine installations or developing and implementing new maintenance procedures.

- Master Technician/Specialist

These are highly experienced technicians, often with over 15 years in the field, who possess expert-level knowledge and skills in specific areas. They may specialize in certain engine types, diagnostic techniques, or regulatory compliance. Due to their specialized knowledge and ability to handle the most complex issues, they command the highest salaries within the technician ranks. Examples include troubleshooting recurring engine performance issues that other technicians cannot resolve or serving as a technical expert for a particular engine type.

In essence, the correlation between experience level and remuneration for aerospace propulsion technicians is directly proportional. Each stage of career progression brings increased responsibilities, enhanced skill sets, and greater value to the employer, which is reflected in corresponding salary increases. Continued professional development and specialization further augment earning potential throughout a technician’s career.

2. Geographic Location

Geographic location significantly influences compensation for aerospace propulsion technicians due to variations in cost of living, regional demand for skilled labor, and the concentration of aerospace-related industries. Areas with higher living costs, such as major metropolitan regions or states with robust aerospace sectors, typically offer higher salaries to offset expenses and attract qualified personnel. This relationship is driven by economic principles of supply and demand; locations with a greater need for technicians and a limited supply will generally see increased wage rates.

For example, a technician working in Seattle, Washington, home to Boeing’s manufacturing facilities, may earn a higher salary compared to an equally qualified technician in a rural area with fewer aerospace job opportunities. Similarly, locations near major military bases or government research facilities often present higher-paying opportunities due to the specialized skills required and the competition for talent. The presence of large maintenance, repair, and overhaul (MRO) facilities also impacts regional salary levels, as these centers require a constant influx of skilled technicians. Therefore, understanding regional differences in compensation is crucial for technicians considering relocation or career advancement.

In summary, geographic location is a critical factor in determining compensation for these specialists. Variations in cost of living and industry concentration directly impact salary levels. By considering regional differences, technicians can make informed decisions regarding career opportunities and maximize their earning potential. Further research into specific location-based compensation data is recommended for those seeking to optimize their career trajectory within the field.

3. Employer Type

Employer type exerts a substantial influence on compensation levels for aerospace propulsion technicians. The financial stability, operational scale, and specialized needs of various employers create significant disparities in salary offerings. Major commercial airlines, for example, typically provide more competitive compensation packages compared to smaller regional carriers or general aviation maintenance shops. This is primarily due to the airlines’ larger revenue streams and the demanding nature of maintaining a large fleet of aircraft operating on stringent schedules. A technician working on wide-body jet engines for a major international airline will likely earn more than one servicing smaller turboprop engines for a regional operator. Furthermore, large airlines often have collective bargaining agreements with unions that further influence compensation and benefits.

Maintenance, Repair, and Overhaul (MRO) facilities also represent a significant employer type. These facilities specialize in the overhaul and repair of aircraft engines and components. The size and scope of MRO operations vary greatly, impacting salary levels. Larger MROs that handle contracts from major airlines and military organizations tend to offer higher pay compared to smaller, independent MROs serving private aircraft owners. Government agencies, such as the Federal Aviation Administration (FAA) or the Department of Defense (DoD), are another employer type. These positions often offer competitive salaries and comprehensive benefits packages, albeit with potentially more bureaucratic structures. The specialized nature of work, which might include regulatory oversight or military aircraft maintenance, contributes to the compensation structure.

The employer’s commitment to employee training and development also indirectly affects salary. Companies that invest heavily in providing technicians with ongoing training on the latest engine technologies and maintenance procedures are more likely to attract and retain skilled personnel, leading to higher overall compensation levels. Therefore, understanding the characteristics and compensation practices of different employer types is essential for aerospace propulsion technicians seeking to maximize their earning potential. Choosing the right employer can have a profound impact on long-term career satisfaction and financial security.

4. Certifications Held

The correlation between certifications held and compensation levels for aerospace propulsion technicians is demonstrably strong. Advanced certifications signify specialized expertise and a commitment to professional development, directly influencing earning potential. The attainment of certifications beyond the basic FAA Airframe and Powerplant (A&P) license validates an individual’s mastery of specific engine types or maintenance procedures, thereby increasing their value to employers. For instance, a technician certified on Pratt & Whitney PW4000 series engines is better positioned to command a higher salary at an airline operating aircraft powered by those engines, compared to a technician holding only the A&P license. This effect stems from the reduced training costs and enhanced efficiency a certified technician brings to the role.

Engine-specific certifications, offered by manufacturers like Rolls-Royce, General Electric, and CFM International, demonstrate a technician’s competency in maintaining particular engine models. These certifications often require intensive training courses and rigorous examinations. Obtaining such certifications provides tangible proof of proficiency, allowing technicians to negotiate higher salaries. Furthermore, holding certifications in specialized areas such as non-destructive testing (NDT) or borescope inspection can also lead to increased compensation. These skills are crucial for ensuring the safety and reliability of aircraft engines, and technicians possessing these qualifications are in high demand. Airlines and MRO facilities prioritize candidates with specialized certifications because they reduce the risk of errors, improve maintenance efficiency, and ensure compliance with regulatory requirements.

In conclusion, certifications held function as a quantifiable measure of skill and expertise, directly impacting an aerospace propulsion technician’s earning capacity. While experience and other factors contribute to overall compensation, certifications provide a distinct advantage in the job market and justify higher salary expectations. Investing in relevant certifications is a strategic career move, demonstrating commitment to the profession and ultimately leading to increased financial rewards.

5. Specific Skills

The nexus between specific skills and compensation for professionals in aerospace propulsion maintenance is direct and quantifiable. Remuneration reflects the value assigned to demonstrable expertise, particularly those skills aligning with current industry demands. Specialized knowledge and proficiency in areas such as advanced diagnostics, engine-specific maintenance, and regulatory compliance correlate positively with earning potential. The ability to effectively troubleshoot complex engine malfunctions, perform intricate repairs, and interpret technical documentation differentiates highly compensated technicians from those with more general skill sets. Technicians possessing niche skills that address specific industry needs may command premium salaries, due to the reduced training investment and immediate operational contributions they offer.

Practical examples underscore this connection. A technician proficient in borescope inspections, a non-destructive testing method for evaluating internal engine components, minimizes disassembly and repair time, thus reducing operational costs. This proficiency translates to higher value and increased earning potential. Likewise, expertise in maintaining newer generation engines, such as those incorporating advanced composite materials or digital engine control systems (FADEC), is highly sought after. The shortage of technicians skilled in these emerging technologies creates a competitive market, driving up salary offers. Furthermore, competence in data analysis and predictive maintenance techniques is gaining prominence. Technicians able to leverage data to identify potential issues before they escalate, reducing downtime and improving overall engine performance, are increasingly valued.

In summary, the development and acquisition of specific, in-demand skills is paramount for aerospace propulsion technicians seeking to maximize their earning potential. The financial rewards directly reflect the ability to contribute to operational efficiency, reduce maintenance costs, and ensure regulatory compliance. Continual investment in skill enhancement is not merely a professional development strategy but a financial imperative in this dynamic and technically demanding field. Furthermore, understanding the specific skills prioritized by employers allows technicians to strategically focus their training efforts, maximizing their return on investment.

6. Union Affiliation

The presence or absence of union representation significantly influences compensation packages for aerospace propulsion technicians. Collective bargaining agreements negotiated by unions often establish standardized wage scales, benefits packages, and working conditions that can differ substantially from those offered in non-union environments. The extent of this influence depends on the strength and bargaining power of the specific union, as well as the employer’s relationship with organized labor.

- Standardized Wage Scales

Union contracts typically establish minimum hourly wage rates based on experience and skill level. These scales provide a degree of predictability and equity in compensation, reducing the potential for wage disparities based on factors unrelated to performance. For example, a union contract may stipulate a specific hourly rate for a technician with five years of experience holding an A&P license, irrespective of individual negotiation skills. This standardization can result in higher base pay for some technicians compared to non-union counterparts.

- Negotiated Benefits Packages

Unions negotiate comprehensive benefits packages on behalf of their members, often including health insurance, retirement plans, paid time off, and other perks. The collective bargaining power of a union allows it to secure more favorable terms and lower costs for these benefits compared to what individual technicians might obtain independently. For instance, a union may negotiate a health insurance plan with lower premiums and better coverage than what is available to non-union technicians employed by the same company.

- Job Security Provisions

Union contracts frequently include provisions related to job security, such as seniority-based layoffs and grievance procedures for disciplinary actions. These protections can reduce the risk of job loss and ensure fair treatment in the workplace. While job security does not directly translate to a higher salary, it provides a greater sense of stability and can influence an individual’s willingness to accept a lower-paying union position compared to a higher-paying but less secure non-union role.

- Overtime and Premium Pay

Union contracts typically specify overtime rates and premium pay for working holidays, weekends, or other non-standard shifts. These provisions can significantly increase annual earnings for technicians who work frequent overtime or are required to work on off-peak hours. For example, a union contract may mandate double-time pay for working on a major holiday, providing a substantial financial incentive for technicians willing to work during these times.

In summary, union affiliation has a multifaceted impact on the earning potential of aerospace propulsion technicians. While not all union positions necessarily pay more than non-union roles, the standardized wage scales, negotiated benefits packages, job security provisions, and overtime pay regulations collectively contribute to a more stable and potentially more lucrative compensation structure. The strength and bargaining power of the specific union, as well as the employer’s relationship with organized labor, ultimately determine the extent of this influence.

Frequently Asked Questions

This section addresses common inquiries regarding compensation for professionals specializing in the maintenance and repair of aircraft propulsion systems, providing clarity on factors influencing earning potential.

Question 1: What is the average annual compensation for an aerospace propulsion technician?

The average annual remuneration varies significantly based on experience, location, and employer. However, publicly available data indicates a broad range, often influenced by regional demand and specialized skill sets. It is advisable to consult industry-specific salary surveys for current figures.

Question 2: Does location impact the annual compensation significantly?

Indeed. Geographic location plays a substantial role. Areas with high concentrations of aerospace manufacturing, maintenance facilities, or major airports typically offer higher salaries due to increased demand and a potentially higher cost of living.

Question 3: How does experience affect the potential salary for technicians?

Experience is a key determinant. Entry-level technicians generally receive lower compensation compared to seasoned professionals with several years of experience and specialized expertise. Progressively complex tasks and leadership responsibilities commensurate with experience warrant increased remuneration.

Question 4: Are there particular certifications that significantly increase earning potential?

Yes. Certifications beyond the basic FAA Airframe and Powerplant (A&P) license, such as engine-specific certifications from manufacturers like Pratt & Whitney or Rolls-Royce, can enhance earning prospects. These certifications validate proficiency in specific engine models.

Question 5: Do unionized positions typically offer higher compensation compared to non-union roles?

Union affiliation can influence compensation. Collective bargaining agreements often establish standardized wage scales and benefits packages that may differ substantially from non-union environments. However, the extent of this impact varies depending on the union’s bargaining power.

Question 6: How does the type of employer (airline, MRO, government) affect total compensation?

Employer type is a significant factor. Major airlines typically provide more competitive compensation packages compared to smaller regional carriers or independent maintenance shops. Government agencies and large MRO facilities also offer varying levels of remuneration.

In summation, an understanding of experience, location, certifications, union affiliation, and employer type is essential for assessing compensation expectations in this field. Diligent research and consideration of these factors can greatly contribute to informed career decisions.

The subsequent sections will delve into industry trends and future projections for aerospace propulsion technician salaries.

Aerospace Propulsion Technician Salary

The preceding exploration has illuminated the multifaceted nature of compensation within the aerospace propulsion maintenance sector. Key determinants, including experience, geographic location, employer type, certifications, specific skill sets, and union affiliation, collectively shape earning potential. Each element contributes uniquely to the overall financial landscape, demonstrating the importance of strategic career planning and continuous professional development for maximizing remuneration. The industry’s demand for qualified professionals, coupled with technological advancements, further influences the valuation of expertise and specialized skills.

Understanding these dynamics is paramount for both aspiring and established technicians. In a field where safety and efficiency are paramount, the economic rewards reflect the critical role these professionals play in ensuring the operational integrity of aircraft propulsion systems. As the aerospace industry continues to evolve, a proactive approach to skill enhancement and career management will remain essential for securing competitive compensation and sustaining long-term professional success.