A significant engineering and manufacturing presence focused on aerospace systems is located in the Portland, Oregon metropolitan area. This facility is a key component of a larger corporation specializing in aircraft electronics, communication, and related technologies. Its activities support the development and production of equipment for both commercial and government aviation sectors.

The facility contributes substantially to the local economy through employment opportunities and technological innovation. It provides a platform for skilled engineers, technicians, and manufacturing personnel to engage in cutting-edge projects. Historically, this location has been integral to the advancement of aviation technology, contributing to improved aircraft safety, efficiency, and passenger experience.

The following sections will delve into the specific functions performed at this location, the technologies developed there, and the impact the facility has on the regional aerospace industry and the broader community. These topics will illuminate its ongoing role in shaping the future of flight.

Operational Insights

The following insights are derived from analysis of a specific aerospace facility in the Portland, Oregon area, offering valuable considerations for businesses operating in similar high-technology manufacturing environments.

Tip 1: Strategic Location Selection: Proximity to a skilled workforce and existing technology infrastructure is paramount. A Portland location benefits from a strong engineering talent pool and access to established supply chains.

Tip 2: Emphasis on Engineering Excellence: A commitment to employing and developing highly skilled engineers is crucial for maintaining a competitive edge in aerospace technology. Continuous training and professional development are essential.

Tip 3: Focus on Advanced Manufacturing Techniques: Investment in state-of-the-art manufacturing equipment and processes is necessary to produce high-quality aerospace components efficiently. Automation and precision manufacturing are key considerations.

Tip 4: Robust Quality Control Procedures: Stringent quality control measures are indispensable to meet the rigorous safety standards of the aerospace industry. Comprehensive testing and inspection protocols must be implemented throughout the manufacturing process.

Tip 5: Strong Supply Chain Management: Maintaining reliable and efficient supply chains is vital for ensuring timely production and minimizing disruptions. Strategic partnerships with key suppliers are beneficial.

Tip 6: Cultivate Industry Partnerships: Collaboration with universities, research institutions, and other aerospace companies fosters innovation and provides access to emerging technologies.

Tip 7: Adherence to Regulatory Compliance: Strict compliance with all relevant aviation regulations and industry standards is non-negotiable. Maintaining certifications and conducting regular audits are essential.

Implementing these principles contributes to enhanced operational efficiency, product quality, and overall success within the aerospace sector. This approach maximizes the facility’s ability to innovate and meet the evolving demands of the aviation market.

The final section will provide a comprehensive summary and closing remarks regarding this important element of the aerospace landscape.

1. Engineering Expertise

Engineering expertise is a cornerstone of operations at the Collins Aerospace facility in Portland, Oregon. It fuels the design, development, and testing of advanced aerospace solutions, contributing significantly to the company’s competitive edge and technological advancements within the industry. This expertise spans multiple disciplines and is essential for maintaining the facility’s standing as a leader in aerospace innovation.

- Systems Engineering

Systems engineering is critical for integrating diverse technologies into cohesive aerospace systems. At the Portland facility, this involves managing the complex interactions between avionics, communication systems, and other aircraft components. For example, engineers design and test integrated flight management systems that optimize aircraft performance and safety. This ensures seamless operation and adherence to stringent aerospace standards.

- Electrical and Electronics Engineering

This facet focuses on the design and development of electronic hardware and software for aerospace applications. Engineers at the Portland location work on cutting-edge projects involving embedded systems, signal processing, and power management. Their work contributes to the creation of more efficient and reliable avionics systems, as exemplified by the development of advanced radar systems for weather detection and navigation.

- Mechanical Engineering

Mechanical engineering expertise is essential for the design and analysis of structural components and mechanical systems used in aircraft. In Portland, this involves the development of lightweight, high-strength materials and the optimization of mechanical designs for improved performance and durability. An example is the design of actuation systems for flight controls, ensuring precise and reliable operation under extreme conditions.

- Software Engineering

Software engineering plays a crucial role in the development of flight-critical software for aerospace applications. Engineers at the facility develop and test software that controls flight systems, manages communication protocols, and provides real-time data analysis. This includes the creation of sophisticated algorithms for autonomous flight control and the development of secure communication systems to prevent cyber threats.

The collective impact of these engineering disciplines is evident in the advanced aerospace solutions developed and manufactured at the Collins Aerospace Portland facility. These solutions enhance aircraft safety, improve operational efficiency, and contribute to the advancement of aviation technology, reinforcing the importance of a highly skilled and multidisciplinary engineering workforce.

2. Manufacturing Capabilities

Manufacturing capabilities form a critical element of the Collins Aerospace operation in Portland, Oregon. This aspect encompasses the facilities, equipment, processes, and expertise required to produce a range of aerospace components and systems. The scale and sophistication of these capabilities directly influence the facility’s ability to meet the demands of the aviation industry.

- Precision Machining

Precision machining is central to producing high-tolerance parts for aerospace applications. The Portland facility utilizes advanced CNC (Computer Numerical Control) machines to create components with exacting specifications. For example, critical parts for flight control systems, such as actuators and valves, are manufactured using precision machining techniques. This ensures the reliability and performance necessary for safe aircraft operation. The ability to produce such components in-house contributes to greater control over quality and lead times.

- Electronics Assembly

The assembly of electronic components is another key manufacturing capability. This involves the placement, soldering, and testing of circuit boards and electronic modules used in avionics systems. The facility maintains a cleanroom environment to prevent contamination and ensure the integrity of sensitive electronic components. An example is the assembly of flight management systems, which require the integration of numerous electronic components to provide accurate navigation and flight control. These capabilities are essential for producing reliable avionics systems that meet stringent performance standards.

- Testing and Validation

Rigorous testing and validation processes are integral to verifying the performance and reliability of manufactured products. The Portland facility employs a range of testing equipment and procedures to simulate real-world operating conditions. This includes environmental testing, vibration testing, and electromagnetic compatibility (EMC) testing. For example, completed avionics systems undergo extensive testing to ensure they can withstand extreme temperatures, altitudes, and electromagnetic interference. Such comprehensive testing ensures compliance with aviation regulations and enhances product safety.

- Supply Chain Integration

Effective supply chain integration is critical for managing the flow of materials and components into the manufacturing process. The Portland facility works closely with a network of suppliers to ensure timely delivery of high-quality materials. This involves coordinating with vendors, managing inventory levels, and implementing quality control measures. An example is the procurement of specialized alloys used in aircraft structural components. Proper supply chain management minimizes disruptions and ensures that the facility can meet production schedules efficiently.

These manufacturing capabilities, when combined, provide a comprehensive platform for producing advanced aerospace systems at the Collins Aerospace facility in Portland. The interplay of precision machining, electronics assembly, rigorous testing, and effective supply chain integration enables the facility to deliver high-quality products that meet the demanding requirements of the aviation industry. This operational prowess contributes significantly to the company’s overall success and its role as a leading provider of aerospace solutions.

3. Regional Employment

The aerospace facility in Portland, Oregon, serves as a significant driver of regional employment, creating a multitude of job opportunities directly and indirectly. This facility requires a diverse workforce, ranging from highly skilled engineers and technicians to manufacturing personnel and administrative staff. The presence of this facility in the Portland area provides employment opportunities that might not otherwise exist, contributing to the economic vitality of the region. The demand for skilled labor, in turn, stimulates local educational institutions to offer relevant training programs, further bolstering the workforce. For example, local community colleges and universities often tailor their curriculum to meet the specific needs of the aerospace industry, ensuring a steady supply of qualified candidates.

The impact extends beyond direct employment. Supporting industries and services also benefit from the facility’s presence, creating a ripple effect that expands employment opportunities. These include suppliers of raw materials, equipment maintenance providers, logistics companies, and various service providers. Real estate values and the demand for housing in the surrounding areas may also increase as a result of the facility’s employment base. Furthermore, the high-tech nature of the aerospace sector attracts other technology-related businesses to the region, fostering a cluster of innovation and economic growth. This clustering effect generates further employment opportunities and strengthens the region’s overall economic resilience.

In summary, the correlation between the aerospace facility and regional employment is substantial. It provides direct job creation, stimulates educational development, and fosters a broader ecosystem of supporting industries and services. Understanding this interconnectedness is crucial for regional economic planning and development strategies, ensuring that the area remains competitive and attractive to both businesses and residents. The facility’s contributions to regional employment are therefore a vital component of its overall impact on the Portland, Oregon area.

4. Technological Innovation

Technological innovation is a driving force within the Collins Aerospace facility located in Portland, Oregon, influencing not only product development but also manufacturing processes and operational efficiency. This commitment to advancement ensures the facility remains competitive and contributes to broader advancements in the aviation industry.

- Advanced Avionics Systems

This facet focuses on the development of next-generation flight control systems, navigation technologies, and communication equipment. For example, the Portland facility may be involved in designing integrated avionics suites that enhance situational awareness for pilots and improve aircraft safety. These systems often incorporate cutting-edge sensor technology and data processing algorithms to optimize flight performance. The integration of such advanced avionics contributes to increased fuel efficiency, reduced pilot workload, and enhanced overall operational effectiveness.

- Sustainable Aviation Technologies

The push for more environmentally friendly aviation solutions necessitates innovative approaches to aircraft design and operation. The facility could be involved in researching and developing technologies to reduce emissions, improve fuel efficiency, and explore alternative energy sources. This might include work on hybrid-electric propulsion systems, advanced aerodynamic designs, or the integration of sustainable aviation fuels (SAF). Such efforts align with industry-wide goals to minimize the environmental impact of air travel.

- Digital Transformation Initiatives

Digital transformation involves leveraging data analytics, artificial intelligence, and cloud computing to improve operational efficiency and decision-making. The Portland facility might implement smart manufacturing techniques that utilize sensor data and machine learning algorithms to optimize production processes and reduce waste. Additionally, data analytics could be applied to predictive maintenance, enabling proactive identification and resolution of potential equipment failures. These digital initiatives enhance productivity, reduce costs, and improve the overall reliability of operations.

- Cybersecurity Measures

With increasing reliance on interconnected systems, cybersecurity becomes a critical area of technological innovation. The facility may be involved in developing and implementing robust cybersecurity measures to protect aircraft systems and sensitive data from cyber threats. This includes the design of secure communication protocols, the implementation of intrusion detection systems, and the development of incident response plans. These cybersecurity efforts are essential for maintaining the safety and integrity of air travel in an increasingly complex digital landscape.

The convergence of these technological innovations at the Collins Aerospace Portland facility not only enhances the company’s product offerings but also contributes to the broader advancement of the aviation industry. Through continuous investment in research and development, the facility remains at the forefront of technological progress, addressing the evolving needs of the global aerospace market. The development of systems like head-up displays (HUDs) or enhanced vision systems (EVS) serve as prime examples of such contributions.

5. Aerospace Systems

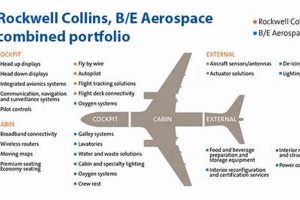

Aerospace systems, encompassing a broad range of technologies and components used in aircraft and spacecraft, are fundamentally linked to the operations at the Collins Aerospace facility in Portland, Oregon. This facility contributes directly to the design, development, and manufacturing of various integral components of these complex systems, thereby playing a vital role in the aviation industry.

- Avionics Integration

Avionics, encompassing the electronic systems used on aircraft, represent a significant focus at the Portland facility. These systems include flight management, navigation, communication, and surveillance equipment. Collins Aerospace integrates these systems to enhance aircraft safety, efficiency, and performance. For instance, advanced flight management systems developed at this location enable precise navigation and optimized flight paths, reducing fuel consumption and emissions. The integration of these avionics components is crucial for the safe and efficient operation of modern aircraft.

- Cabin Management Systems

Cabin management systems enhance passenger comfort and convenience during air travel. These systems include in-flight entertainment, lighting, temperature control, and communication capabilities. The Portland facility may contribute to the development and manufacturing of components for these systems. For example, advanced display systems and connectivity solutions can be integrated into cabin management systems to provide passengers with a more enjoyable and productive flight experience. These systems contribute to customer satisfaction and the overall quality of air travel.

- Communication and Connectivity Solutions

Reliable communication and connectivity are essential for modern aircraft operations. Collins Aerospace develops and manufactures communication systems that enable pilots to communicate with air traffic control, as well as provide passengers with in-flight internet access. The Portland facility may be involved in the development of satellite communication systems, data links, and other connectivity solutions. These systems facilitate real-time data transfer and enable enhanced communication between aircraft and ground stations, improving operational efficiency and safety.

- Power and Control Systems

Effective power and control systems are critical for the operation of all aircraft functions. The Portland facility might contribute to the development of power distribution systems, engine control units, and other related components. These systems ensure that electrical power is supplied to various aircraft systems in a controlled and reliable manner. For instance, advanced engine control units can optimize engine performance, reduce fuel consumption, and minimize emissions. These systems are essential for ensuring the safe and efficient operation of aircraft.

The functionalities described, encompassing avionics, cabin enhancements, communication infrastructure, and power regulation, represent key domains where Collins Aerospace Portland contributes to the advancement and refinement of aerospace systems. These efforts ensure safer, more efficient, and more comfortable air travel experiences for passengers and flight crews alike.

6. Economic Impact

The economic impact of a specific aerospace facility in Portland, Oregon, is multifaceted and extends beyond direct employment figures. Its presence generates economic activity throughout the region, influencing various sectors and contributing to overall prosperity.

- Direct Employment and Wages

The facility directly employs a significant number of individuals, ranging from engineers and technicians to manufacturing personnel and administrative staff. These jobs provide wages and benefits to local residents, contributing to household income and consumer spending. For example, a facility employing 1,000 individuals with an average salary of \$75,000 generates \$75 million in direct wages annually. These earnings support local businesses and contribute to the tax base.

- Indirect and Induced Impacts

The facility’s operations create indirect and induced economic impacts through its supply chain and the spending of its employees. Indirect impacts arise from the facility’s purchases of goods and services from local suppliers, while induced impacts result from the spending of employee wages in the local economy. For instance, a facility requiring specialized equipment or materials supports local manufacturers and distributors. The spending of employee wages at restaurants, retail stores, and service providers further stimulates economic activity. These multiplier effects significantly amplify the facility’s overall economic contribution.

- Tax Revenue Generation

The facility contributes to local, state, and federal tax revenues through various mechanisms. Property taxes are paid on the facility’s land and buildings, while income taxes are collected from employees. Sales taxes are generated through purchases made by the facility and its employees. These tax revenues support public services, such as education, infrastructure, and public safety. For example, a facility with a significant property value contributes substantially to local school districts and municipal governments.

- Innovation and Technological Spillovers

The facility’s research and development activities can lead to innovation and technological spillovers that benefit other industries and businesses. The development of new technologies and processes can create opportunities for commercialization and entrepreneurship. For instance, a facility developing advanced materials or manufacturing techniques may spin off new companies or license its technologies to other firms. These innovation spillovers enhance the region’s competitiveness and attract further investment.

The economic impact of the aerospace facility in Portland, Oregon, is substantial and far-reaching. Through direct employment, indirect and induced impacts, tax revenue generation, and innovation spillovers, the facility contributes significantly to the region’s economic prosperity and competitiveness. Understanding these multifaceted economic effects is crucial for policymakers and community leaders to support the continued growth and success of the aerospace industry in the area.

7. Industry Contribution

The aerospace facility in Portland, Oregon, substantially contributes to the broader aerospace industry through multiple avenues, ranging from technological innovation and workforce development to economic investment and supply chain support. Its role can be analyzed through cause-and-effect relationships: investments in research and development (cause) lead to technological advancements (effect) benefiting the entire industry; workforce training programs (cause) result in a skilled labor pool (effect) improving industry-wide productivity and innovation. This contribution is not merely incidental but is an essential component of its operational identity. The facility’s impact can be observed in the adoption of technologies it pioneers by other industry players and the absorption of its trained workforce into the broader aerospace sector.

A practical example of this industry contribution is the development of advanced avionics systems. The facility’s engineers may design and test new flight management systems that improve fuel efficiency and reduce pilot workload. These innovations, once proven, are often adopted by aircraft manufacturers and airlines worldwide, leading to safer and more efficient air travel. Additionally, the facility’s participation in industry consortia and partnerships facilitates the sharing of knowledge and best practices, further amplifying its impact. Moreover, the presence of such a significant aerospace entity in the Portland area attracts other related businesses and suppliers, creating a cluster effect that strengthens the region’s overall aerospace capabilities.

In summary, the aerospace facility in Portland significantly contributes to the industry through technological advancement, workforce development, economic impact, and supply chain support. The facility fosters beneficial ripple effects across the industry. Recognizing and supporting such contributions is crucial for fostering continued innovation, maintaining a skilled workforce, and ensuring the long-term health and competitiveness of the broader aerospace sector. The ongoing challenge involves sustaining investment in research and development and nurturing collaborations to address future industry needs.

Frequently Asked Questions

The following questions address common inquiries regarding the operations, impact, and relevance of the Collins Aerospace facility located in Portland, Oregon. These answers are intended to provide factual information and clarify prevalent areas of interest.

Question 1: What specific aerospace systems are designed and manufactured at the Collins Aerospace Portland facility?

The facility focuses on advanced avionics, communication systems, and increasingly, cabin management components. While specific product lines are proprietary, general areas include flight management systems, display technologies, and connectivity solutions for commercial and military aircraft. The facility specializes in integrating these systems into cohesive solutions for aircraft manufacturers.

Question 2: What is the approximate number of employees at the Collins Aerospace Portland location, and what types of jobs are available?

While precise figures fluctuate, the facility represents a substantial employer in the Portland metropolitan area. Available positions span engineering disciplines (electrical, mechanical, software), manufacturing, quality control, supply chain management, and administrative functions. Open positions are typically posted on the Collins Aerospace corporate website.

Question 3: How does the Collins Aerospace Portland facility contribute to the local economy?

The facility contributes to the local economy through direct employment, the payment of wages and taxes, and the procurement of goods and services from local suppliers. It also supports indirect employment in related industries. The presence of a high-technology aerospace firm in the region fosters innovation and attracts other related businesses.

Question 4: What are the primary engineering disciplines employed at the Collins Aerospace Portland facility?

Key engineering disciplines include systems engineering, electrical engineering, mechanical engineering, software engineering, and aerospace engineering. These engineers work collaboratively on the design, development, and testing of aerospace systems and components. A multidisciplinary approach is essential for addressing the complex challenges of the aviation industry.

Question 5: How does the Collins Aerospace Portland facility ensure the quality and reliability of its products?

Stringent quality control measures are implemented throughout the manufacturing process. This includes rigorous testing, inspection, and validation procedures to ensure compliance with industry standards and regulatory requirements. The facility maintains certifications and conducts regular audits to verify adherence to quality management systems. Emphasis is placed on preventing defects and ensuring product reliability.

Question 6: What sustainability initiatives are being pursued at the Collins Aerospace Portland facility?

While specific initiatives are subject to change, Collins Aerospace has made public commitments to reducing its environmental impact. These initiatives often include efforts to improve energy efficiency, reduce waste, and minimize emissions. The Portland facility likely participates in these broader corporate sustainability efforts, though local activities may vary. Specific project details are typically communicated through corporate reports.

In summary, the Collins Aerospace Portland facility is a vital component of the aerospace industry and the Portland region. Its contributions extend to technological innovation, economic development, and workforce opportunity.

The following section will provide information on contacting the company and other relevant resources.

Conclusion

The preceding examination of Collins Aerospace Portland Oregon has illuminated its significant role in the aerospace sector and its substantial contribution to the regional economy. The facilitys engineering expertise, manufacturing capabilities, impact on regional employment, and technological innovation collectively underscore its importance as a key player in the global aerospace landscape. The facility’s ongoing operations demonstrate a commitment to quality, technological advancement, and economic development.

Further investigation into the specific projects and technological developments at Collins Aerospace Portland Oregon would undoubtedly yield deeper insights. Continued evaluation of its operational strategies, and contribution to workforce development is warranted for regional stakeholders. The trajectory of Collins Aerospace Portland Oregon will likely continue to be shaped by the evolving demands of the aerospace industry, technological advancements, and global economic conditions.

![Understanding Collins Aerospace Market Cap [Insights] Innovating the Future of Flight with Reliable Aviation Solutions Understanding Collins Aerospace Market Cap [Insights] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-112-300x200.jpg)

![U.S. Hubs: Collins Aerospace US Locations Guide [2024] Innovating the Future of Flight with Reliable Aviation Solutions U.S. Hubs: Collins Aerospace US Locations Guide [2024] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-97-300x200.jpg)

![Collins Aerospace Holiday Schedule: [Year] Dates & Guide Innovating the Future of Flight with Reliable Aviation Solutions Collins Aerospace Holiday Schedule: [Year] Dates & Guide | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-71-300x200.jpg)