Opportunities within Daher’s aerospace division encompass a wide spectrum of roles, from engineering and manufacturing to supply chain management and administrative functions. These positions are located across various global sites, reflecting the company’s international footprint. For example, a manufacturing engineer might be responsible for optimizing production processes for aircraft components, while a supply chain manager would oversee the procurement and delivery of necessary materials.

The significance of these career paths lies in their contribution to the advancement of aviation technology and the efficient operation of the aerospace industry. They provide individuals with the chance to work on cutting-edge projects and contribute to the development of innovative solutions. Historically, employment in this sector has been a driver of economic growth and technological progress, attracting skilled professionals from diverse backgrounds.

The subsequent sections will delve into specific areas within Daher’s aerospace operations, examining the qualifications, responsibilities, and potential career trajectories associated with them. Focus will be given to the skills and experience valued by the company and the impact these positions have on the overall success of Daher’s aerospace endeavors.

The following provides essential guidance for individuals pursuing positions within Daher’s aerospace sector. Emphasis is placed on preparation, understanding the company’s values, and highlighting relevant skills.

Tip 1: Research Daher Thoroughly: A comprehensive understanding of Daher’s business units, product lines (aircraft, aerostructures, services), and market position is crucial. Explore the company website, industry publications, and financial reports to gain insights into its strategic objectives.

Tip 2: Align Skills with Specific Job Requirements: Carefully analyze the job description and tailor the resume and cover letter to highlight skills and experiences that directly address the stated requirements. Quantify accomplishments whenever possible (e.g., “Reduced production time by 15%”).

Tip 3: Emphasize Aerospace-Specific Knowledge: Demonstrate familiarity with aerospace industry standards, regulations (e.g., FAA, EASA), and current trends. Knowledge of aircraft design principles, manufacturing processes, or aviation safety protocols is highly valued.

Tip 4: Showcase Problem-Solving Abilities: Aerospace roles often require critical thinking and problem-solving skills. Provide specific examples of situations where analytical skills were used to overcome challenges and achieve positive outcomes. Use the STAR method (Situation, Task, Action, Result) to structure responses during interviews.

Tip 5: Highlight Relevant Certifications and Education: Possessing relevant certifications (e.g., Lean Six Sigma, Project Management Professional) or advanced degrees in aerospace engineering, manufacturing, or a related field can significantly enhance candidacy.

Tip 6: Demonstrate Commitment to Safety and Quality: Safety and quality are paramount in the aerospace industry. Emphasize experience adhering to strict safety protocols, implementing quality control measures, and participating in continuous improvement initiatives.

Tip 7: Network Strategically: Attend industry events, connect with Daher employees on professional networking platforms, and seek informational interviews. Networking can provide valuable insights into the company culture and potential career paths.

Successful navigation of the application process requires diligent preparation and a clear understanding of Daher’s needs and values. By aligning skills and experience with specific job requirements, candidates can increase their chances of securing a position within the company’s aerospace division.

The subsequent discussion will explore the long-term career prospects and growth opportunities available within Daher’s aerospace organization.

1. Engineering Expertise

Engineering expertise forms a cornerstone of Daher’s aerospace operations, driving innovation and ensuring the performance, safety, and reliability of its aircraft and aerospace systems. Possessing significant engineering skill is often a prerequisite for many positions within the company.

- Aerodynamic Design

Aerodynamic design is crucial for optimizing aircraft performance, reducing drag, and improving fuel efficiency. Within Daher aerospace positions, engineers apply computational fluid dynamics (CFD) and wind tunnel testing to refine wing profiles and control surfaces. For example, designing a new winglet configuration to reduce drag on the TBM aircraft would require expertise in aerodynamic principles and simulation software.

- Structural Analysis

Structural analysis ensures the integrity and durability of aircraft components under various load conditions. Engineers in structural analysis roles employ finite element analysis (FEA) to assess stress distribution, fatigue life, and the potential for failure. An example would be analyzing the structural integrity of the fuselage under extreme flight maneuvers, ensuring compliance with safety regulations and preventing structural failures.

- Systems Engineering

Systems engineering involves the integration of various aircraft systems, including avionics, electrical systems, and hydraulic systems, to ensure seamless operation and optimal performance. Professionals in this area are often responsible for defining system requirements, managing interfaces, and conducting system-level testing. For instance, developing a new integrated flight management system requires expertise in software engineering, avionics, and aircraft systems integration.

- Materials Science

Materials science plays a vital role in selecting and characterizing the materials used in aircraft construction. Engineers in this field evaluate the properties of different materials, such as composites, aluminum alloys, and titanium, to optimize strength, weight, and corrosion resistance. Choosing the appropriate composite material for a wing spar requires expertise in materials science, manufacturing processes, and structural performance.

These examples illustrate the diverse applications of engineering expertise within Daher. These skills are crucial for the design, development, and manufacturing of safe, efficient, and innovative aircraft, reflecting the commitment of Daher to engineering excellence in its aerospace endeavors. Career progression within engineering roles requires continuous learning and development to stay abreast of the latest technological advancements and industry best practices.

2. Manufacturing Innovation

Manufacturing innovation is an essential driver of efficiency, quality, and competitiveness within the aerospace industry, directly impacting the nature and scope of career opportunities at Daher. The implementation of advanced manufacturing technologies and processes shapes the skills, responsibilities, and overall impact of manufacturing positions within the company.

- Additive Manufacturing (3D Printing)

Additive manufacturing enables the creation of complex geometries and customized parts with reduced material waste and lead times. Within Daher, this technology is applied to produce tooling, prototypes, and potentially end-use components for aircraft. Implementing additive manufacturing requires expertise in materials science, CAD/CAM software, and process optimization. Job roles range from design engineers specializing in additive manufacturing to technicians operating 3D printing equipment and quality control specialists ensuring the integrity of printed parts.

- Robotics and Automation

The integration of robotics and automation streamlines manufacturing processes, improves precision, and enhances worker safety. Robots are deployed for tasks such as drilling, riveting, painting, and composite layup. Operating and maintaining these automated systems requires skilled technicians with expertise in robotics programming, machine maintenance, and process control. Additionally, industrial engineers are needed to design and optimize automated workflows.

- Digital Manufacturing and IoT

Digital manufacturing involves the use of data analytics, simulation, and the Internet of Things (IoT) to optimize production processes and improve decision-making. Sensors embedded in equipment and machines provide real-time data on performance, enabling predictive maintenance and process optimization. Positions in this area include data analysts, software engineers, and manufacturing engineers with expertise in data acquisition, data analysis, and the development of digital twins.

- Advanced Composites Manufacturing

Advanced composite materials are increasingly used in aircraft construction due to their high strength-to-weight ratio and corrosion resistance. Manufacturing composite components requires specialized techniques such as automated fiber placement (AFP) and resin transfer molding (RTM). Daher needs skilled technicians and engineers specializing in composite materials processing, non-destructive testing (NDT), and quality control to ensure the structural integrity of composite parts.

The incorporation of these innovative manufacturing technologies transforms the landscape of job roles at Daher, demanding a workforce equipped with advanced technical skills and a commitment to continuous learning. These innovations improve production processes, and they drive the need for highly skilled professionals capable of operating, maintaining, and optimizing these advanced systems, contributing to the overall success and competitiveness of Daher’s aerospace operations.

3. Global Supply Chain

The effective management of the global supply chain is critical to Daher’s aerospace operations, influencing numerous career paths and job responsibilities within the organization. Its complexity and scope generate diverse opportunities for professionals with expertise in logistics, procurement, and supply chain management.

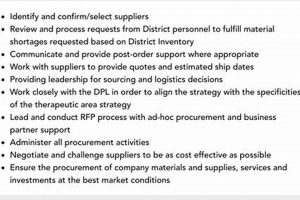

- Procurement and Sourcing

Procurement specialists are responsible for sourcing raw materials, components, and services from suppliers across the globe. These professionals evaluate potential suppliers, negotiate contracts, and ensure compliance with quality standards and regulatory requirements. An example includes sourcing specialized alloys for aircraft engine components from a certified supplier in Europe. The implications for opportunities include roles such as Strategic Sourcing Manager, Procurement Engineer, and Supplier Quality Assurance Specialist.

- Logistics and Transportation

Logistics professionals manage the transportation and warehousing of goods, ensuring timely delivery to Daher’s manufacturing facilities and customer locations. This involves coordinating with freight carriers, customs brokers, and warehouse operators. Consider the task of coordinating the shipment of large aircraft fuselage sections from a manufacturing plant in North America to an assembly line in France. Positions such as Logistics Manager, Transportation Coordinator, and Warehouse Supervisor are essential within this facet.

- Inventory Management

Inventory managers optimize stock levels to minimize holding costs while ensuring the availability of materials for production. They employ forecasting techniques and inventory control systems to manage the flow of materials through the supply chain. The efficient management of spare parts inventory for aircraft maintenance operations, ensuring minimal downtime for customers, exemplifies this function. Career opportunities include Inventory Control Analyst, Demand Planner, and Supply Chain Optimization Specialist.

- Supply Chain Planning and Optimization

Supply chain planners develop strategies to improve the overall efficiency and resilience of the supply chain. They analyze data, identify bottlenecks, and implement solutions to reduce costs, improve delivery times, and mitigate risks. An example is developing a contingency plan to address potential disruptions caused by geopolitical events or natural disasters. Roles such as Supply Chain Planner, Supply Chain Analyst, and Supply Chain Director are integral to this process.

These interconnected facets of the global supply chain highlight the breadth and depth of career opportunities within Daher’s aerospace division. Professionals in these roles contribute to the efficient and reliable flow of materials and components, supporting the company’s ability to meet customer demands and maintain a competitive edge in the global aerospace market. Understanding the intricacies of global supply chain management and associated regulatory frameworks is crucial for individuals aspiring to these positions.

4. Quality Assurance

Quality Assurance (QA) is an inextricable component of roles within Daher’s aerospace sector. The aviation industry operates under stringent safety and regulatory standards; therefore, quality control is not merely a procedural step but a fundamental principle embedded throughout the organization. Consequently, positions at Daher necessitate a strong understanding of QA principles and practices. The absence of robust QA protocols can result in severe consequences, including aircraft malfunctions, safety hazards, and regulatory penalties. A real-life example involves the inspection of composite materials used in aircraft wings. QA personnel verify that the materials meet specified strength and weight requirements before integration into the final product. Failure to identify defects in this stage can compromise the structural integrity of the aircraft.

QA personnel at Daher perform a diverse range of tasks, including inspecting components, monitoring manufacturing processes, conducting audits, and managing documentation. Their responsibilities extend from the initial design phase to the final delivery of the aircraft. Consider the role of a Quality Engineer who works on the production line. This individual is responsible for identifying and addressing any deviations from the established quality standards. This engineer utilizes statistical process control (SPC) to monitor key process parameters and identify trends that may indicate potential quality issues. Furthermore, QA teams collaborate with engineering and manufacturing departments to implement corrective actions and prevent future defects. This collaborative approach ensures that quality is integrated into every stage of the product lifecycle.

In summary, Quality Assurance is not just a department but a pervasive philosophy in Daher’s aerospace operations. Positions within the company demand a commitment to maintaining the highest levels of quality and safety. Meeting this expectation presents ongoing challenges, including adapting to new technologies, managing complex supply chains, and ensuring compliance with evolving regulatory requirements. The practical significance of understanding QA within the context of Daher lies in its direct impact on the reliability, safety, and reputation of the company’s aerospace products and services. Individuals aspiring to positions within Daher must recognize the importance of quality and demonstrate their ability to contribute to a culture of continuous improvement.

5. Regulatory Compliance

Regulatory compliance forms a fundamental and non-negotiable aspect of operations within the aerospace industry, directly shaping the nature and responsibilities of many job roles at Daher. Strict adherence to aviation regulations, set forth by bodies such as the FAA (Federal Aviation Administration) in the United States and EASA (European Aviation Safety Agency) in Europe, is critical for ensuring airworthiness, safety, and operational integrity. Daher employees are directly impacted by these regulations, as their work must consistently meet or exceed these mandated standards. For instance, engineers involved in designing aircraft components must ensure that their designs comply with specific airworthiness directives. Failure to adhere to these directives could result in costly redesigns, production delays, and, more significantly, potential safety risks. This direct cause-and-effect relationship underscores the importance of understanding and implementing regulatory requirements across various job functions.

The implementation of regulatory compliance is a multi-faceted endeavor encompassing design, manufacturing, maintenance, and operational procedures. For instance, Quality Assurance specialists are responsible for meticulously documenting processes, conducting audits, and ensuring that all activities align with regulatory mandates. Maintenance technicians must adhere to approved maintenance schedules and procedures outlined by regulatory agencies, utilizing only certified parts and tools. Moreover, adherence extends to documentation and record-keeping. Accurate and complete documentation is essential for demonstrating compliance during audits and inspections by regulatory authorities. The implications of non-compliance can be severe, ranging from fines and operational restrictions to the grounding of aircraft. Therefore, the ability to navigate and apply regulatory guidelines is an indispensable skill for individuals aspiring to roles at Daher.

In summary, regulatory compliance is not an isolated function but an integrated element of every job role within Daher’s aerospace operations. The constant evolution of aviation regulations poses ongoing challenges, requiring continuous training and adaptation. By understanding and effectively implementing regulatory requirements, Daher employees contribute to the overall safety, reliability, and success of the company. This understanding is not simply theoretical; it translates directly into practical actions that safeguard passengers, protect the company’s reputation, and ensure its continued operation within the highly regulated aerospace environment.

6. Aviation Safety

Aviation safety is a paramount concern within the aerospace industry, intrinsically linked to the responsibilities and expectations of personnel employed in various roles at Daher. The integration of safety considerations into every facet of operation is essential, influencing design, manufacturing, maintenance, and operational procedures.

- Design Engineering for Safety

Design engineers bear the responsibility of incorporating safety features into aircraft design to mitigate potential hazards. This involves conducting rigorous testing, employing fail-safe mechanisms, and adhering to stringent safety standards. An example is designing a redundant flight control system that maintains functionality even in the event of a component failure. This impacts roles directly, as design engineers must possess comprehensive knowledge of aviation safety regulations and implement them proactively.

- Manufacturing Quality Control

Manufacturing processes must adhere to stringent quality control measures to ensure the integrity of aircraft components. QA teams are responsible for inspecting materials, monitoring production processes, and identifying potential defects. Consider a scenario where QA personnel detect a flaw in a critical structural component. This necessitates immediate corrective action and a review of manufacturing processes to prevent recurrence. Opportunities are affected here, demanding a skilled workforce focused on aviation best practices.

- Maintenance and Inspection Procedures

Maintenance technicians play a crucial role in ensuring the continued airworthiness of aircraft through regular inspections and maintenance procedures. These technicians must adhere to strict maintenance schedules, utilize approved parts, and accurately document all maintenance activities. An example involves performing a detailed inspection of an aircraft engine to identify signs of wear or damage, preventing potential failures during flight. Technicians with specialized training in aviation safety protocols are in high demand.

- Operational Safety Management

Operational safety management involves implementing procedures and protocols to minimize risks associated with aircraft operations. This includes pilot training, flight planning, and adherence to safety regulations during flight. A scenario involves pilots following established procedures for responding to emergencies, such as engine failures or adverse weather conditions. Positions requiring pilot certification or expertise in aviation safety management are pivotal in ensuring safe flight operations.

These interconnected facets of aviation safety collectively shape the expectations and responsibilities of professionals across various roles. A commitment to aviation safety is not merely a job requirement but a fundamental value, influencing career trajectories and contributing to the overall safety and reliability of Daher’s aerospace products and services. Prioritizing safety directly influences the success and sustainability in the aviation market.

Frequently Asked Questions Regarding Career Opportunities in Daher’s Aerospace Division

The following addresses common inquiries concerning employment prospects, application procedures, and expectations for individuals seeking positions within Daher’s aerospace sector.

Question 1: What educational qualifications are typically required for engineering positions at Daher?

A bachelor’s degree in aerospace engineering, mechanical engineering, or a related field is generally expected. Advanced degrees, such as a Master’s or Ph.D., may be preferred for specialized roles or research-oriented positions.

Question 2: What types of experience are most valued in manufacturing roles within Daher’s aerospace operations?

Experience in aerospace manufacturing, composite materials processing, CNC machining, or assembly operations is highly relevant. Familiarity with Lean manufacturing principles and quality control methodologies is also advantageous.

Question 3: Does Daher offer opportunities for professional development and training for its employees?

Daher invests in the professional development of its employees through a variety of training programs, mentorship opportunities, and tuition reimbursement for relevant coursework or certifications.

Question 4: What is the company culture like at Daher, and what values does it emphasize?

Daher fosters a culture of innovation, collaboration, and customer focus. The company values integrity, teamwork, and a commitment to excellence in all aspects of its operations.

Question 5: How does Daher ensure the safety and well-being of its employees in its aerospace facilities?

Daher prioritizes employee safety and well-being through comprehensive safety programs, regular training, and adherence to strict safety protocols. The company invests in equipment and procedures to minimize workplace hazards.

Question 6: What are the typical career paths for individuals starting in entry-level positions at Daher’s aerospace division?

Entry-level positions can serve as a foundation for career advancement into roles such as project management, engineering leadership, or specialized technical positions. Career progression is often based on performance, experience, and professional development.

This FAQ section provides a concise overview of key considerations for individuals interested in pursuing career opportunities with Daher’s aerospace division.

Subsequent sections will provide insights into the long-term growth prospects and challenges associated with career paths within Daher’s aerospace organization.

Daher Aerospace Jobs

This exploration has elucidated the multifaceted nature of employment within Daher’s aerospace sector. Key areas of focus included engineering expertise, manufacturing innovation, global supply chain management, quality assurance, regulatory compliance, and aviation safety. The analysis underscored the specific skills and qualifications demanded across these diverse domains, emphasizing the importance of specialized knowledge and continuous professional development.

The information presented serves to inform prospective applicants regarding the demands and opportunities inherent in positions at Daher. Potential candidates should carefully assess their capabilities and align their career aspirations with the requirements of this dynamic and critical industry. Future success hinges on dedication to safety, commitment to quality, and a proactive approach to addressing the evolving challenges within the aerospace landscape.