Positions within the field of air and space vehicle manufacturing, research, and development are critical for advancing technological capabilities. These roles encompass a wide range of specializations, from engineering and design to manufacturing and maintenance, directly contributing to the creation and support of aircraft, spacecraft, and related systems. For example, a design engineer might be involved in creating the next generation of commercial aircraft, while a manufacturing specialist ensures the efficient and precise assembly of satellite components.

The significance of these careers extends beyond individual companies; they are vital for national security, economic growth, and scientific discovery. The individuals employed in these sectors drive innovation, pushing the boundaries of what is possible in air and space exploration. Historically, government investment and private sector initiatives have fueled expansion in these employment opportunities, leading to breakthroughs in propulsion systems, materials science, and automation, which, in turn, generates even greater demand for skilled professionals.

The following discussion explores the specific areas where these openings are most prevalent, the skills and education necessary to secure these roles, and the long-term career prospects within the sector. Furthermore, it examines the impact of emerging technologies on the evolving nature of the work involved and the resources available to those seeking to enter or advance within this dynamic industry.

Guidance for Pursuing Opportunities in Air and Space Vehicle Development

The following suggestions are intended to assist individuals seeking employment in the field of air and space vehicle development. Adherence to these guidelines can improve the likelihood of securing suitable positions and advancing within the sector.

Tip 1: Prioritize Relevant Education: A strong foundation in engineering, mathematics, or physics is crucial. Consider advanced degrees or specialized certifications related to aerospace engineering, mechanical engineering, or a related discipline. For example, a Master’s degree in Aerospace Engineering with a focus on propulsion systems can significantly enhance prospects for roles involving engine design and development.

Tip 2: Develop Specialized Skills: Acquire proficiency in industry-standard software and technologies. This includes CAD/CAM software (e.g., CATIA, SolidWorks), simulation tools (e.g., ANSYS, MATLAB), and programming languages (e.g., Python, C++). Demonstrating competence in these areas is essential for roles involving design, analysis, and simulation.

Tip 3: Seek Internship Opportunities: Internships provide invaluable practical experience and exposure to real-world challenges. Pursue internships with aerospace companies, government agencies (e.g., NASA, ESA), or research institutions. Successful completion of an internship can lead to full-time employment opportunities upon graduation.

Tip 4: Network Strategically: Attend industry conferences, workshops, and career fairs to connect with professionals in the field. Join professional organizations such as the American Institute of Aeronautics and Astronautics (AIAA) to expand your network and stay informed about industry trends. Networking can provide access to unadvertised positions and valuable mentorship opportunities.

Tip 5: Tailor Resumes and Cover Letters: Customize application materials to highlight relevant skills and experience for each specific position. Clearly articulate how your qualifications align with the requirements outlined in the job description. Emphasize accomplishments and quantify results whenever possible to demonstrate the impact of your contributions.

Tip 6: Obtain Necessary Security Clearances: Many positions within the industry, particularly those involving defense-related projects, require security clearances. Investigate the clearance requirements for desired positions and initiate the application process as early as possible. Possessing a security clearance can significantly broaden employment opportunities.

Tip 7: Stay Abreast of Industry Trends: Maintain a continuous learning approach by staying informed about emerging technologies, such as advanced materials, autonomous systems, and sustainable aviation. Read industry publications, attend webinars, and participate in online forums to expand your knowledge and expertise. Demonstrating awareness of industry trends can set you apart from other candidates.

Implementing these recommendations can improve competitiveness in the employment market and facilitate a successful career trajectory within the field of air and space vehicle development. Proactive preparation and strategic networking are essential for achieving long-term professional goals.

The subsequent section will address the impact of evolving technologies and future perspectives within the sector, providing a comprehensive overview of the overall landscape.

1. Engineering Design

Engineering design constitutes a foundational pillar within the air and space vehicle industry. Its influence permeates all stages of product development, from initial conceptualization to detailed schematics and prototype fabrication. The efficacy of engineering design directly impacts a product’s performance, safety, and cost-effectiveness. For instance, innovative wing designs can reduce drag, leading to increased fuel efficiency in commercial aircraft. Similarly, robust structural designs are critical for ensuring the integrity of spacecraft during launch and operation. Positions relating to these design activities are essential within the sector, directly influencing project outcomes.

The connection between engineering design and these career paths extends beyond mere functional roles. Effective design teams necessitate skilled professionals across diverse specializations, including aerodynamics, structural analysis, propulsion systems, and materials science. A real-world illustration is the design of modern jet engines. A dedicated team of engineers is required to optimize the engine’s performance, minimize emissions, and enhance its lifespan. The integration of advanced computational fluid dynamics (CFD) simulations has become a standard practice, enabling engineers to predict and refine designs before physical prototypes are even constructed. Such methods and advancements necessitate specific training and expertise for those employed in the sector.

The practical significance of comprehending this relationship lies in appreciating the multidisciplinary nature of air and space vehicle engineering. Success in these careers often requires a broad understanding of various engineering disciplines and the ability to collaborate effectively across teams. Challenges within the field demand innovative solutions, placing a premium on individuals possessing both theoretical knowledge and practical skills. Future developments in engineering design, such as additive manufacturing and artificial intelligence-assisted design tools, will further shape the landscape of these employment opportunities.

2. Manufacturing Processes

The efficiency and precision of manufacturing processes are intrinsically linked to the availability and nature of positions within the air and space vehicle industry. These processes, encompassing fabrication, assembly, and testing, directly determine the quality, reliability, and cost of the final product. Consequently, skilled professionals are required to oversee and optimize these processes, creating a substantial demand for specialized expertise. For instance, the manufacturing of turbine blades for jet engines necessitates advanced techniques like precision casting and machining, alongside stringent quality control measures. The effective implementation of these techniques necessitates a skilled workforce, thereby driving demand within the job sector. A failure in any of these stages can result in defective parts, leading to costly rework or, worse, compromising the safety of the vehicle. This risk underscores the critical need for qualified personnel in these areas.

The adoption of advanced manufacturing technologies further reinforces the connection between manufacturing processes and employment opportunities. The integration of automation, robotics, and additive manufacturing (3D printing) is transforming the industry, requiring workers with specialized skills in areas like programming, robotics maintenance, and materials science. As an example, the use of 3D printing to produce complex structural components allows for greater design freedom and reduced material waste. However, it also creates a need for engineers and technicians who can operate and maintain the 3D printing equipment, develop new materials, and ensure the quality of the printed parts. Therefore, advanced manufacturing methods simultaneously require more qualified operators and improve efficiency, ultimately improving profitability.

In summation, the role of manufacturing processes is central to defining employment opportunities within air and space vehicle industries. As manufacturing technology evolves and the demand for increasingly complex and reliable vehicles grows, the need for skilled professionals in this area will continue to expand. Addressing this need will require investments in education and training programs to equip workers with the skills necessary to thrive in this rapidly changing landscape. By understanding the importance of optimized manufacturing techniques, potential employees are better prepared to meet industry needs, and ensure the continued success of air and space vehicle sectors.

3. Systems Integration

Systems integration, in the context of air and space vehicle development, represents the crucial process of combining disparate components and subsystems into a unified, functioning whole. This process directly creates positions within the sector because each subsystem, from avionics to propulsion, necessitates specialized engineering expertise. The increasing complexity of modern air and space vehicles demands proficient integration engineers and technicians capable of ensuring seamless operation and interoperability. As an example, integrating a new radar system into an existing aircraft requires careful consideration of power requirements, data interfaces, and aerodynamic effects. Failure to properly integrate such a system could result in compromised aircraft performance or even safety hazards. The demand for qualified personnel is therefore directly proportional to the complexity and innovation within the air and space industries.

Furthermore, the rise of increasingly autonomous systems in aerospace has amplified the importance of effective systems integration. The integration of artificial intelligence, sensor networks, and control algorithms requires a sophisticated understanding of software and hardware interaction. Consider the development of autonomous drone technology for package delivery. The integration process involves coordinating GPS navigation, obstacle avoidance sensors, and automated flight control systems. Specialized engineers are required to validate these integrations, requiring a deep understanding of diverse technologies. The need for experts in this area is not just limited to the design phase. Continuous monitoring, calibration, and updating of the integrated systems create ongoing employment prospects within this area.

In summary, systems integration constitutes a core activity within air and space vehicle development, directly influencing the demand for skilled professionals. The ongoing advancements in aerospace technology are fueling the demand for systems integration positions with expertise in a wide range of engineering disciplines. Understanding the interconnectedness of systems integration and employment opportunities within the sector is crucial for prospective job seekers and educational institutions seeking to prepare graduates for the evolving needs of the industry. Investment in training and development programs focused on systems integration is vital to maintaining a skilled workforce and ensuring continued innovation within the air and space industries.

4. Quality Assurance

Quality assurance (QA) is inextricably linked to available positions relating to the manufacturing, maintenance, and operation of air and space vehicles. QA processes, which encompass inspection, testing, and documentation, are essential to guarantee product reliability and safety. The aerospace industry operates under strict regulatory frameworks, such as those imposed by the FAA and other international bodies, mandating rigorous quality control at every stage of production. This regulatory environment directly fuels the demand for qualified QA professionals, including inspectors, auditors, and compliance specialists. Defective components in an aircraft or spacecraft can have catastrophic consequences, necessitating meticulous attention to detail and adherence to established protocols. Therefore, the complexity and risk associated with air and space systems elevate the importance of QA roles and the number of positions available.

The practical implications of QA extend beyond simply detecting defects. Effective QA systems contribute to process improvement by identifying root causes of errors and implementing corrective actions. For example, statistical process control techniques can be used to monitor manufacturing processes and detect deviations from established norms, allowing for proactive intervention. Furthermore, QA professionals play a crucial role in ensuring that products meet customer specifications and performance requirements. Failure to meet these standards can result in costly rework, delays, and damage to a company’s reputation. The implementation of lean manufacturing principles and Six Sigma methodologies is increasingly common in the aerospace industry, and QA professionals are instrumental in driving these initiatives. These experts drive efficiencies, ensure compliance, and improve production outputs.

In conclusion, quality assurance represents an indispensable element of air and space vehicle development, with a direct and substantial impact on the creation and maintenance of specific employment roles. The stringent safety and regulatory requirements that govern the industry ensure a persistent demand for skilled QA professionals. While challenges remain in adapting QA processes to rapidly evolving technologies and materials, ongoing investment in training and education is crucial to maintaining a competent workforce and ensuring the continued safety and reliability of air and space vehicles. A strong commitment to QA is not merely a regulatory obligation but a competitive advantage, driving innovation and bolstering consumer confidence.

5. Research and Development

Research and development (R&D) serves as the engine of innovation within the air and space vehicle sector. The activities undertaken in R&D departments directly influence the creation of new technologies, materials, and processes, thereby shaping the nature and scope of available positions in the field. Effective R&D programs drive the evolution of air and space travel, and fundamentally expand the job opportunities available in the industry.

- Advanced Materials Research

The development of lighter, stronger, and more heat-resistant materials is critical for improving the performance and efficiency of air and space vehicles. R&D efforts in this area involve exploring new alloys, composites, and nanomaterials. For example, the development of carbon fiber reinforced polymers has enabled the construction of lighter aircraft structures, resulting in reduced fuel consumption. Positions within this domain include materials scientists, chemical engineers, and manufacturing specialists, all collaborating to innovate with new compounds. The progression of materials research drives job creation by increasing the complexity and value of the final products.

- Propulsion Systems Innovation

R&D related to propulsion systems focuses on developing more efficient, cleaner, and powerful engines for aircraft and spacecraft. This includes research into alternative fuels, advanced combustion techniques, and electric propulsion systems. For instance, the development of turbofan engines with higher bypass ratios has significantly improved fuel efficiency in commercial aviation. Positions in this area include mechanical engineers, aerospace engineers, and combustion specialists. Propulsion research and development pushes the envelope of air and space travel, improving efficiency, and, as such, increases demand for skilled engineers and technicians.

- Autonomous Systems Development

The integration of autonomous systems into air and space vehicles is transforming the industry, leading to the development of unmanned aerial vehicles (UAVs), autonomous spacecraft, and advanced flight control systems. R&D in this area involves developing sophisticated algorithms, sensor technologies, and communication networks. Self-flying commercial airlines are a future possibility, enabled by research and development. Positions in autonomous systems involve software engineers, robotics specialists, and control systems engineers. The increased complexity of the technology creates new specialized engineering and design job opportunities.

- Aerodynamics and Flight Control Research

Aerodynamics and flight control research aims to improve the aerodynamic efficiency, stability, and maneuverability of air and space vehicles. This involves conducting wind tunnel tests, computational fluid dynamics (CFD) simulations, and flight testing to validate new designs and control strategies. A laminar flow control system for aircraft wings is an example, as are the control systems for rockets. This area also includes aerospace engineers, fluid dynamics specialists, and control systems engineers. Aerodynamic optimization has been proven to improve efficiency and increase lift capacity.

These facets demonstrate the deep interconnection between ongoing research and development efforts and the subsequent creation and evolution of positions within the air and space vehicle industries. As R&D initiatives push technological boundaries, they not only enhance the capabilities of existing systems but also generate demand for a skilled workforce capable of designing, manufacturing, and maintaining these advancements. Continued investment in R&D is therefore critical to ensuring the long-term competitiveness and growth of the aerospace sector, creating the engineering opportunities.

Frequently Asked Questions Concerning Aerospace Positions

The following addresses common inquiries regarding employment opportunities within the aerospace sector. These questions and answers are intended to provide clarity and guidance to individuals seeking to enter or advance within the industry.

Question 1: What are the primary educational qualifications necessary for these roles?

A bachelor’s degree in a relevant engineering field (e.g., aerospace, mechanical, electrical) is generally considered the minimum requirement. Advanced degrees, such as a Master’s or Ph.D., are often preferred for research and development positions or specialized engineering roles.

Question 2: What specific skills are most valued by employers in the aerospace industry?

Employers typically seek candidates with strong analytical skills, problem-solving abilities, and proficiency in relevant software tools (e.g., CAD/CAM, simulation software). Strong communication and teamwork skills are also highly valued due to the collaborative nature of many aerospace projects.

Question 3: Are security clearances a common requirement for employment?

Yes, security clearances are frequently required, particularly for positions involving defense-related projects or access to classified information. The specific level of clearance required varies depending on the nature of the work and the employer’s requirements.

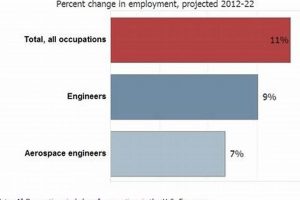

Question 4: What is the long-term career outlook within these sectors?

The long-term career outlook is generally positive, driven by increasing demand for air travel, space exploration, and national defense. However, the industry is subject to cyclical fluctuations, and employment levels can be affected by economic conditions and government spending policies.

Question 5: What are some of the emerging trends shaping the future of aerospace careers?

Emerging trends include the development of electric aircraft, autonomous systems, and advanced materials. These trends are creating new opportunities for engineers and scientists with expertise in these areas.

Question 6: How can individuals best prepare themselves for these roles?

In addition to obtaining a relevant education and developing necessary skills, individuals should seek internships or co-op experiences to gain practical experience. Networking with industry professionals and staying abreast of industry trends are also crucial for career advancement.

Understanding these common inquiries is vital for prospective job seekers to plan their education and experience. A solid understanding of required credentials and skillsets can increase the potential for career success.

The subsequent segment will analyze case studies of successful professionals in the field and offer lessons learned from their career journeys.

Conclusion

This exploration of “idd aerospace jobs” underscores the critical role these positions play in driving innovation and progress within the air and space sectors. The discussion has highlighted the diverse range of specializations, from engineering design and manufacturing processes to systems integration, quality assurance, and research and development. Each area necessitates a highly skilled workforce committed to upholding the highest standards of safety and performance.

The continued growth and competitiveness of the air and space industries are inextricably linked to ongoing investment in education, training, and research. Addressing the challenges and capitalizing on the opportunities presented by emerging technologies will require a concerted effort from industry, government, and academia. A commitment to fostering a skilled workforce and supporting technological advancements is essential for ensuring the continued success and expansion of these pivotal sectors.