Employment opportunities within Primus Aerospace, a company specializing in the manufacturing of precision components for the aerospace and defense industries, encompass a diverse range of roles. These positions span engineering, machining, quality control, program management, and administrative support. An example includes CNC machinists responsible for operating and maintaining computer-controlled machinery to fabricate intricate parts according to strict specifications.

Securing a position with the company offers access to a sector characterized by technological advancement and demanding quality standards. Benefits may include contributing to critical projects related to national security and commercial aviation. Historically, organizations in this sector have provided long-term career stability and competitive compensation packages to attract and retain skilled personnel.

The following sections will delve into specific career paths, required qualifications, the application process, and potential for professional growth within this organization and the broader aerospace manufacturing field.

Successfully pursuing openings at Primus Aerospace requires a strategic approach. Emphasis should be placed on aligning qualifications and experience with the company’s specific needs and demonstrating a commitment to the rigorous standards of the aerospace industry.

Tip 1: Research Company Specializations: Prior to applying, conduct thorough research into Primus Aerospace’s core competencies, the types of components it manufactures, and its key clients. This knowledge will enable candidates to tailor their applications and interviews to highlight relevant skills and experience.

Tip 2: Highlight Relevant Certifications and Training: Aerospace manufacturing often necessitates specialized certifications and training. If applicable, emphasize certifications such as AS9100, NADCAP, or specific CNC machining qualifications. Detail any relevant training courses or workshops completed.

Tip 3: Quantify Accomplishments: Resumes and cover letters should showcase quantifiable achievements from previous roles. For example, instead of stating “Improved machining efficiency,” specify “Improved machining efficiency by 15% through implementation of new tooling strategies.”

Tip 4: Tailor the Resume: Generic resumes are unlikely to succeed. Customize the resume for each position by prioritizing the skills and experience most relevant to the specific job description. Use keywords from the job posting within the resume and cover letter.

Tip 5: Prepare for Technical Interviews: Positions involving engineering, machining, or quality control will likely require technical interviews. Practice answering technical questions related to manufacturing processes, materials science, and quality assurance procedures.

Tip 6: Demonstrate Problem-Solving Abilities: Highlight examples from prior experiences where problem-solving skills were utilized to overcome manufacturing challenges. This demonstrates adaptability and a proactive approach to resolving issues.

Tip 7: Emphasize Teamwork Skills: Aerospace manufacturing relies on collaboration between various departments. Highlight experiences that demonstrate the ability to work effectively within a team environment to achieve common goals.

By focusing on the above strategies, applicants can significantly increase their chances of securing a desirable position. A well-prepared and targeted approach is crucial for navigating the competitive landscape of aerospace employment.

The subsequent sections will address frequently asked questions and offer insights into long-term career progression within the company.

1. Engineering Specializations

Engineering specializations are a cornerstone of “Primus Aerospace jobs,” shaping the company’s capabilities and project successes. These specialized roles drive innovation and efficiency in aerospace component manufacturing.

- Design Engineering

Design engineers are responsible for creating and refining the blueprints for aerospace components. Their role involves using CAD/CAM software to develop models, analyze stress, and ensure components meet stringent performance requirements. For instance, a design engineer might design a lightweight yet robust bracket for an aircraft engine, balancing weight reduction with structural integrity. In the context of openings at Primus Aerospace, design engineering positions demand expertise in materials science, mechanical engineering principles, and relevant aerospace standards.

- Manufacturing Engineering

Manufacturing engineers focus on optimizing the manufacturing processes. They determine the most efficient methods for producing components, selecting tooling, and programming CNC machines. An example involves a manufacturing engineer streamlining the production of a complex turbine blade, reducing cycle time while maintaining precision. A person in this role in a company would require knowledge of lean manufacturing principles, process improvement techniques, and CNC programming languages.

- Quality Engineering

Quality engineers ensure that all manufactured components meet the required quality standards. They develop and implement quality control procedures, conduct inspections, and analyze data to identify areas for improvement. Consider a quality engineer overseeing the dimensional inspection of a landing gear component, ensuring it adheres to the tight tolerances specified by the design. These jobs call for expertise in quality management systems, statistical process control, and metrology techniques.

- Materials Engineering

Materials engineers specialize in the selection and application of materials used in aerospace components. They analyze material properties, conduct testing, and ensure that the chosen materials can withstand the extreme conditions encountered in flight. For example, a materials engineer might select a specific titanium alloy for a critical structural component due to its high strength-to-weight ratio and corrosion resistance. Such a position needs expertise in materials science, metallurgy, and non-destructive testing methods.

These engineering specializations are interconnected and essential for successful project outcomes. Roles are typically defined by specific skill sets and experience levels, ranging from entry-level positions to senior leadership roles. Primus Aerospace values individuals who possess a strong technical foundation, problem-solving skills, and a commitment to continuous improvement within the aerospace industry.

2. Machining Expertise

Machining expertise forms a foundational element within “Primus Aerospace jobs,” directly impacting the company’s ability to produce high-precision components. The demand for individuals skilled in operating and programming Computer Numerical Control (CNC) machines is consistently high, given the intricate geometries and tight tolerances required in aerospace manufacturing. Without proficient machinists, the engineering designs cannot be translated into tangible parts, directly affecting production timelines and overall product quality. For example, the precise machining of turbine blades, which require complex three-dimensional surfaces, necessitates highly skilled CNC operators who can interpret complex programs and adjust machine parameters to meet exacting specifications. The absence of such expertise would lead to unacceptable deviations and potential component failure.

The significance of machining expertise extends beyond mere operation of machinery. Skilled machinists contribute to process improvement by identifying potential bottlenecks and suggesting optimized tooling or cutting strategies. Consider the machining of aircraft landing gear components; experienced machinists can recommend modifications to the machining sequence to minimize material waste and reduce machining time. Furthermore, their knowledge of material properties and machining parameters is crucial in preventing defects such as surface cracks or dimensional inaccuracies. Failure to accurately execute machining processes can result in components that do not meet the stringent requirements of the Federal Aviation Administration (FAA), causing potential safety risks and financial repercussions.

In conclusion, machining expertise is not merely a desirable attribute but a critical requirement for many roles within Primus Aerospace. The company’s success hinges on the ability to attract and retain skilled machinists who can consistently produce components that meet the highest standards of precision and quality. Continuous investment in training and technology is vital to ensure that the workforce possesses the necessary skills to maintain a competitive edge in the aerospace manufacturing industry, particularly as the industry becomes more complex.

3. Quality Assurance

Quality assurance forms an indispensable link to every facet of opportunities at Primus Aerospace. The stringent demands of the aerospace industry dictate that every component, from the smallest fastener to the most complex structural element, must meet uncompromising standards. Consequently, positions directly related to quality control, inspection, and process validation are critical within the organization. The cause is clear: failure to adhere to quality standards can lead to catastrophic consequences, ranging from operational inefficiencies to critical system failures in aircraft. As a result, Primus Aerospace dedicates significant resources to maintaining a robust quality assurance system. Without meticulous quality assurance personnel, the company’s reputation and operational viability are at risk.

The practical significance of understanding the relationship between quality assurance and employment is multifaceted. Quality assurance positions demand a thorough understanding of aerospace manufacturing processes, materials science, and metrology. An inspector, for instance, must possess the ability to interpret complex engineering drawings, utilize precision measurement equipment, and identify deviations from specified tolerances. Similarly, quality engineers are tasked with developing and implementing quality control plans, analyzing statistical data to identify trends, and leading corrective action initiatives. These jobs require not only technical proficiency but also meticulous attention to detail and unwavering commitment to upholding quality standards. Real-world examples include inspectors identifying micro-cracks in turbine blades, preventing premature failure, or quality engineers optimizing manufacturing processes to reduce scrap rates.

In summary, the connection between quality assurance and career prospects at Primus Aerospace is inextricably linked. Quality assurance is not merely a supporting function, but an integral element that underpins the company’s operations and reputation. As the aerospace industry continues to evolve, the demand for skilled professionals in quality assurance will only intensify. Navigating those careers successfully requires a deep understanding of manufacturing processes, unwavering commitment to quality, and continuous improvement within the specialized manufacturing processes.

4. Program Management

Program management constitutes a critical function within Primus Aerospace, impacting the execution and profitability of manufacturing projects. Opportunities in program management demand a unique combination of technical understanding, leadership skills, and organizational capabilities.

- Project Planning and Execution

Program managers are responsible for defining project scope, establishing timelines, and allocating resources to ensure projects are completed on time and within budget. For instance, a program manager might oversee the manufacturing of a complex aircraft component, coordinating engineering, machining, and quality control teams to meet delivery deadlines. This role necessitates proficiency in project management methodologies, such as Gantt charts and critical path analysis, as well as the ability to mitigate risks and resolve conflicts. Without effective program management, projects can suffer from delays, cost overruns, and quality issues.

- Customer Relationship Management

Program managers serve as the primary point of contact for customers, maintaining clear communication and addressing any concerns that may arise during the project lifecycle. An example includes a program manager collaborating with an aerospace customer to define component specifications, providing regular progress updates, and addressing any engineering challenges. This aspect requires strong interpersonal skills, the ability to negotiate effectively, and a commitment to customer satisfaction. Fostering strong customer relationships is essential for securing repeat business and maintaining a positive reputation.

- Risk Management

Program managers are tasked with identifying and mitigating potential risks that could impact project outcomes. This involves conducting risk assessments, developing contingency plans, and implementing risk mitigation strategies. Consider a program manager anticipating potential supply chain disruptions and proactively sourcing alternative suppliers to ensure the timely delivery of critical materials. Effective risk management minimizes the likelihood of project delays, cost overruns, and quality defects.

- Financial Oversight

Program managers are accountable for managing project budgets, tracking expenses, and ensuring projects remain financially viable. This necessitates a strong understanding of financial principles, cost accounting, and budget management techniques. An example includes a program manager monitoring project costs, identifying potential cost-saving opportunities, and implementing strategies to stay within budget. Effective financial oversight is crucial for maximizing profitability and ensuring the long-term sustainability of the organization.

The aforementioned facets underscore the significant role program managers play within Primus Aerospace. Individuals in these positions are instrumental in driving project success, fostering customer relationships, and ensuring financial accountability. The demand for skilled program managers within the aerospace industry will likely remain strong as companies seek to improve efficiency, reduce costs, and maintain competitiveness. As companies become more complex, the need for program managers will continue to be needed.

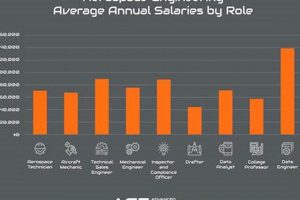

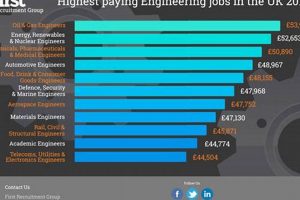

5. Competitive Compensation

Competitive compensation is a critical element in attracting and retaining qualified personnel within Primus Aerospace, particularly given the specialized skills and demanding nature of aerospace manufacturing. It directly influences the company’s ability to secure individuals with the requisite expertise to maintain operational efficiency and quality standards.

- Attracting Skilled Talent

A robust compensation package, including salary and benefits, serves as a primary motivator for skilled professionals seeking employment. The aerospace industry demands highly trained engineers, machinists, and quality control specialists. A competitive salary reflects the value of these skills and encourages qualified candidates to choose Primus Aerospace over competing organizations. For example, a seasoned CNC machinist with expertise in aerospace-grade materials is more likely to accept a position offering a higher wage and comprehensive benefits compared to a lower-paying alternative.

- Retaining Existing Employees

Competitive compensation is equally important for retaining valuable employees. Regular salary reviews, performance-based bonuses, and comprehensive benefits packages can incentivize employees to remain with the company long-term. The loss of experienced personnel can result in significant disruptions to production schedules and increased training costs for new hires. Therefore, a commitment to competitive compensation is a strategic investment in employee retention and organizational stability. Consider an experienced quality engineer who possesses in-depth knowledge of the company’s processes and products; a competitive salary and benefits package will increase the likelihood of that individual remaining with Primus Aerospace.

- Enhancing Employee Morale and Productivity

Adequate compensation can contribute to improved employee morale and increased productivity. When employees feel valued and fairly compensated, they are more likely to be engaged in their work and committed to achieving company goals. This translates into higher quality workmanship, reduced errors, and increased efficiency. A compensated employee may be more likely to take the time to identify and implement process improvements, leading to increased efficiency and reduced costs for the company.

- Maintaining a Competitive Edge

Offering competitive compensation enables Primus Aerospace to remain competitive within the broader aerospace manufacturing industry. Companies that consistently offer attractive compensation packages are better positioned to attract and retain top talent, which in turn drives innovation, improves product quality, and enhances overall competitiveness. Maintaining an advantageous wage structure assists the company in securing contracts and market share within the industry, contributing to long-term success.

In conclusion, competitive compensation is inextricably linked to securing and retaining skilled workers for Primus Aerospace. It contributes significantly to the success, efficiency, and product quality of the organization. By offering attractive compensation packages, Primus Aerospace is better positioned to compete, maintain a skilled workforce, and sustain long-term growth.

Frequently Asked Questions Regarding Primus Aerospace Employment

This section addresses common inquiries concerning career opportunities at Primus Aerospace, providing detailed insights into the application process, employee expectations, and potential career trajectories.

Question 1: What specific qualifications are typically required for engineering positions within Primus Aerospace?

Engineering roles generally necessitate a bachelor’s degree in a relevant field such as mechanical, aerospace, or manufacturing engineering. Advanced degrees or specialized certifications may be preferred for senior-level positions. Experience with CAD/CAM software, materials science, and aerospace standards is highly valued.

Question 2: Does Primus Aerospace offer apprenticeship programs or entry-level opportunities for individuals without extensive experience?

The availability of apprenticeship programs or entry-level positions varies depending on the current needs of the company. Interested individuals should regularly monitor the company’s career website for updated listings and specific requirements for each role.

Question 3: What is the typical career progression path for machinists within Primus Aerospace?

A common career path for machinists starts with entry-level positions operating CNC machines. With experience and continued training, machinists can advance to roles such as CNC programmers, lead machinists, or manufacturing engineers.

Question 4: What types of benefits are typically offered to employees at Primus Aerospace?

While specific benefits packages may vary, Primus Aerospace generally offers comprehensive benefits, including health insurance, dental insurance, vision insurance, paid time off, and retirement plans. Details regarding specific benefits are usually provided during the interview process.

Question 5: How does Primus Aerospace approach employee training and development?

Primus Aerospace recognizes the importance of continuous learning and development. The company may offer training programs, tuition reimbursement, and opportunities for employees to expand their skill sets and advance their careers.

Question 6: What is the company culture like at Primus Aerospace, and what values are emphasized?

Primus Aerospace’s culture typically emphasizes precision, quality, teamwork, and continuous improvement. Adherence to aerospace standards and a commitment to excellence are highly valued. Further information regarding company culture can often be gleaned from employee testimonials and company publications.

Key takeaways emphasize the importance of possessing relevant qualifications, understanding career pathways, and valuing continuous professional development. A thorough comprehension of these factors is crucial for successfully navigating potential employment opportunities.

The subsequent section explores resources available to individuals seeking roles within the aerospace sector.

Primus Aerospace Jobs

This exploration has provided a detailed overview of employment opportunities at Primus Aerospace. The analysis encompassed engineering specializations, machining expertise, quality assurance protocols, program management functions, and the importance of competitive compensation. Each facet represents a critical component of the company’s operational framework and underscores the high standards expected of its workforce.

The aerospace manufacturing sector demands precision, expertise, and unwavering commitment to quality. Potential candidates are encouraged to diligently assess their qualifications, align their skills with company requirements, and pursue continuous professional development. Success in securing employment, and contributing to the industry’s future, hinges upon a dedication to excellence and a profound understanding of the demanding nature of aerospace work.

![Top Countries: Best Aerospace Engineering Jobs [2024] Innovating the Future of Flight with Reliable Aviation Solutions Top Countries: Best Aerospace Engineering Jobs [2024] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-91-300x200.jpg)