Practical applications that allow learners in the field to synthesize theoretical knowledge with hands-on experience. These opportunities can encompass a broad spectrum of activities, ranging from designing aircraft components to simulating flight dynamics, and frequently involve collaborative efforts to mirror real-world engineering practices.

The undertaking of such practical assignments serves as a vital bridge between academic understanding and professional competence. Benefits include enhanced problem-solving skills, the fostering of innovation, and the development of teamwork abilities crucial for success in the aerospace sector. Historically, these experiential elements have been integral to aerospace curricula, adapting over time to incorporate advancements in technology and evolving industry demands.

The subsequent sections will explore specific categories of these practical assignments, detail the skills they cultivate, and examine how they contribute to a well-rounded education in the field.

Guidance for Aerospace Engineering Practical Applications

The successful execution of practical assignments demands meticulous planning, rigorous analysis, and a commitment to iterative refinement. The following recommendations aim to enhance the learning experience and improve outcomes during these educational endeavors.

Tip 1: Define Clear Objectives: Before commencing any work, establish specific, measurable, achievable, relevant, and time-bound (SMART) goals. A well-defined scope ensures focused effort and facilitates accurate evaluation of progress.

Tip 2: Prioritize Thorough Research: A strong foundation in relevant literature, existing technologies, and industry standards is essential. Comprehensive research informs design choices and mitigates potential errors.

Tip 3: Embrace Simulation and Modeling: Utilizing simulation software allows for virtual testing and optimization of designs before physical prototyping. This approach reduces costs and identifies potential flaws early in the development process.

Tip 4: Foster Collaborative Teamwork: Effective communication and collaboration are critical in a team setting. Clearly define roles, responsibilities, and communication channels to ensure seamless coordination.

Tip 5: Document Progress Systematically: Maintaining detailed records of all design decisions, analyses, and test results provides valuable insights for future reference and facilitates troubleshooting.

Tip 6: Seek Expert Guidance: Actively solicit feedback from faculty advisors, industry professionals, and experienced peers. Constructive criticism contributes to improved designs and enhanced understanding.

Tip 7: Adhere to Ethical Considerations: All practical applications must adhere to ethical standards, including responsible use of resources, intellectual property rights, and environmental impact assessment.

By adhering to these guidelines, individuals enhance their technical competence, foster professional development, and contribute to the advancement of the field.

The concluding section will summarize the importance of practical assignments and highlight their role in preparing the next generation of aerospace engineers.

1. Design

Design, in the context of practical applications for aerospace engineering students, is not merely an aesthetic consideration but a fundamental process that dictates the functionality, safety, and efficiency of aerospace systems. It is the iterative and systematic approach to conceiving, developing, and refining aerospace components, systems, and vehicles.

- Conceptual Design

This initial phase involves defining mission requirements and generating potential solutions to meet those needs. It includes trade studies, feasibility assessments, and the preliminary selection of materials and technologies. For instance, when designing a new UAV, students might explore different wing configurations, propulsion systems, and payload capacities based on the intended surveillance mission.

- Detailed Design

Following the conceptual phase, detailed design involves creating precise specifications for each component, including dimensions, tolerances, and material properties. This stage relies heavily on CAD software, engineering calculations, and simulations to ensure structural integrity and aerodynamic performance. Examples include designing the internal structure of an aircraft wing to withstand specific load factors or optimizing the shape of a turbine blade for maximum efficiency.

- Design for Manufacturing

This critical aspect focuses on optimizing designs for efficient and cost-effective manufacturing processes. Considerations include selecting appropriate manufacturing techniques (e.g., machining, casting, 3D printing), minimizing material waste, and simplifying assembly procedures. Students might redesign a complex bracket to be produced using a single casting process instead of multiple machined parts, thereby reducing manufacturing costs.

- Design Validation and Verification

The final step involves validating the design through rigorous testing and analysis to ensure it meets all performance requirements and safety standards. This can include wind tunnel testing, finite element analysis, and flight simulations. Students may conduct structural tests on a scale model of an aircraft fuselage to verify its ability to withstand aerodynamic loads or simulate flight performance under various environmental conditions.

The design process, therefore, is a cornerstone of practical assignments in aerospace engineering, demanding a deep understanding of engineering principles, innovative problem-solving skills, and the ability to integrate multiple disciplines to create viable aerospace solutions. These assignments provide invaluable experience, equipping students with the skills necessary to tackle complex engineering challenges in their future careers.

2. Analysis

Within practical assignments, analysis forms the critical bridge between theoretical concepts and real-world applications. It involves the systematic examination of designs, systems, and data to predict performance, identify potential weaknesses, and optimize outcomes. A successful assignment hinges on the accuracy and thoroughness of its analytical component, directly influencing the validity of conclusions and the effectiveness of proposed solutions. For example, in a project focused on designing a new aircraft wing, structural analysis using finite element methods is essential to determine its ability to withstand aerodynamic loads without failure. Similarly, computational fluid dynamics simulations provide insights into airflow patterns around the wing, enabling optimization for lift and drag characteristics.

The significance of analytical techniques extends beyond structural and aerodynamic assessments. Performance analysis of propulsion systems, thermal analysis of electronic components, and reliability analysis of critical systems are all integral parts of comprehensive project evaluations. Incorrect or incomplete analysis can lead to flawed designs, increased risks, and ultimately, project failure. Consider a project involving the development of a satellite’s power system. Accurate thermal analysis is crucial to ensure that electronic components operate within their specified temperature ranges in the harsh environment of space. Failure to account for heat dissipation and thermal gradients could result in component overheating, malfunction, and mission failure.

In summary, analysis provides the evidence-based foundation upon which informed decisions are made within practical assignments. By employing a range of analytical tools and techniques, future aerospace engineers can develop designs that are not only innovative but also safe, efficient, and reliable. Mastering these analytical skills is therefore paramount to success in both academic projects and professional endeavors, enabling graduates to confidently address the complex challenges inherent in the aerospace field.

3. Simulation

Simulation plays a pivotal role in aerospace engineering practical assignments, offering a virtual environment for testing and refining designs before physical implementation. This capability allows for the exploration of diverse scenarios and the identification of potential issues early in the development process, reducing costs and mitigating risks. The use of simulation tools enables students to model complex systems, such as aircraft aerodynamics, satellite orbits, and structural behavior under extreme conditions. For example, in a project involving the design of a new aircraft wing, computational fluid dynamics (CFD) simulations can be employed to analyze airflow patterns and optimize the wing’s shape for maximum lift and minimal drag. This iterative process, involving simulation, analysis, and design refinement, is crucial for achieving optimal performance and safety.

Furthermore, simulation extends beyond performance analysis to encompass system integration and validation. Students can utilize simulation software to model the interactions between different subsystems within an aerospace vehicle, such as the propulsion system, avionics, and control systems. This allows for the identification of potential incompatibilities and the optimization of system-level performance. In the context of satellite design, simulation can be used to model the satellite’s orbit, attitude control, and communication links, ensuring that the satellite can effectively perform its intended mission. Such integrated simulations are essential for verifying the functionality and reliability of complex aerospace systems before launch or deployment.

In conclusion, simulation is an indispensable tool for aerospace engineering students, providing a cost-effective and efficient means of designing, analyzing, and validating aerospace systems. By leveraging simulation software, students can gain valuable insights into the behavior of complex systems, identify potential problems, and optimize designs for performance, safety, and reliability. The ability to effectively utilize simulation tools is a critical skill for future aerospace engineers, enabling them to tackle the challenges of designing and developing advanced aerospace technologies.

4. Fabrication

Fabrication, in the context of aerospace engineering practical applications, represents the physical realization of designs and analyses. It transforms theoretical concepts into tangible components and systems. This stage is critical as it exposes students to the challenges of translating digital models into physical objects, accounting for material properties, manufacturing tolerances, and assembly procedures. A design for an aircraft wing, however elegant in simulation, must be manufacturable using available resources and processes. Fabrication serves as a crucial validation step, revealing unforeseen issues related to material selection, structural integrity, and assembly feasibility that simulations may not capture. Consider a student team tasked with building a small-scale rocket engine. The design phase, incorporating thermodynamic and fluid dynamic analyses, yields a theoretical blueprint. However, the fabrication phase, involving machining, welding, and assembly of the engine components, introduces real-world constraints and potential deviations from the ideal model. Incorrect welding techniques, for instance, could compromise the structural integrity of the combustion chamber, leading to catastrophic failure during testing. The practical significance lies in understanding that a successful aerospace project necessitates a design that is not only theoretically sound but also practically realizable through appropriate fabrication methods.

The specific fabrication techniques employed depend on the project’s scope and complexity. Composite materials fabrication, involving layup and curing processes, is relevant for projects focused on lightweight structures. Additive manufacturing, or 3D printing, enables the creation of complex geometries and customized components. Traditional machining techniques, such as milling and turning, remain essential for producing precision parts with tight tolerances. Each method presents unique challenges and requires specific skills and knowledge. A team building a UAV might utilize 3D printing to rapidly prototype airframe components, allowing for iterative design improvements based on physical testing. Simultaneously, they might employ traditional machining to fabricate critical engine mounts requiring high strength and dimensional accuracy. Selecting the appropriate fabrication technique requires considering factors such as material properties, production volume, cost, and available equipment.

In conclusion, fabrication provides a crucial link between design and reality in aerospace engineering practical applications. It reinforces theoretical knowledge by exposing students to the practical challenges of manufacturing aerospace components and systems. By engaging in fabrication, students develop essential skills in material selection, manufacturing processes, and quality control, preparing them for the demands of the aerospace industry. The successful completion of fabrication tasks demonstrates not only an understanding of design principles but also the ability to translate those principles into tangible, functional hardware.

5. Testing

Within the context of practical assignments in aerospace engineering, testing serves as the empirical validation phase. It transforms theoretical predictions and simulated performance into tangible evidence, providing crucial insights into the functionality, reliability, and safety of aerospace components and systems.

- Functional Testing

Functional testing assesses whether a system or component performs its intended functions according to specifications. For instance, a team designing an autopilot system will conduct functional tests to verify its ability to maintain altitude, heading, and speed under various flight conditions. These tests often involve simulated flight environments or hardware-in-the-loop simulations where the autopilot is connected to a flight simulator. Data collected during functional testing provides evidence of compliance with design requirements and reveals any functional deficiencies that require correction.

- Structural Testing

Structural testing evaluates the mechanical integrity of aerospace structures under static and dynamic loads. This can involve subjecting a wing section to bending and torsional forces to determine its load-bearing capacity or performing vibration tests on a satellite payload to simulate launch conditions. Structural testing is crucial for ensuring that components can withstand the stresses encountered during flight or space operation, preventing catastrophic failures. Finite element analysis results are often compared to experimental data to validate models and identify areas of potential weakness.

- Environmental Testing

Aerospace systems are subjected to harsh environmental conditions, including extreme temperatures, vacuum, radiation, and vibration. Environmental testing simulates these conditions to assess the system’s ability to withstand them without degradation in performance. For example, a satellite component might undergo thermal vacuum testing to evaluate its ability to operate in the vacuum and extreme temperature variations of space. Similarly, electronic components may be subjected to radiation testing to assess their susceptibility to radiation-induced failures. Environmental testing ensures that systems are robust and reliable in their intended operating environments.

- Flight Testing

Flight testing represents the ultimate validation of an aircraft’s design. It involves operating the aircraft under realistic flight conditions to assess its performance, stability, and control characteristics. Flight testing is conducted by qualified test pilots and engineers who carefully monitor the aircraft’s behavior and collect data on parameters such as airspeed, altitude, engine performance, and control surface deflections. This data is then analyzed to verify that the aircraft meets its performance specifications and complies with safety regulations. Flight testing is a complex and highly regulated process that is essential for ensuring the safety and airworthiness of new aircraft designs.

These testing methodologies are integral to practical experiences, forming the backbone of experiential learning. They serve not only as validation tools but also as invaluable educational opportunities, allowing students to confront real-world engineering challenges, refine their analytical skills, and develop a deep understanding of the intricacies involved in creating safe and effective aerospace systems.

6. Collaboration

The effective execution of practical assignments hinges significantly on collaborative teamwork. Aerospace engineering projects, by their nature, are multidisciplinary endeavors requiring diverse skill sets and areas of expertise. Students must integrate knowledge from aerodynamics, propulsion, structures, control systems, and electronics to achieve project objectives. Collaboration fosters knowledge sharing and leverages the strengths of individual team members. Consider the construction of a small-scale wind tunnel: one student might specialize in the aerodynamic design of the test section, while another focuses on the mechanical design of the supporting structure, and a third manages the data acquisition system. Without effective communication and coordinated effort, such projects face significant challenges.

Inefficient collaboration leads to several adverse effects. Duplication of effort, conflicting design choices, and schedule delays can undermine project success. Conversely, successful collaborative initiatives promote innovation, efficiency, and enhanced learning outcomes. Effective collaboration necessitates clearly defined roles and responsibilities, open communication channels, and established conflict resolution mechanisms. Project management tools and methodologies facilitate the coordination of tasks, tracking of progress, and management of resources. For instance, implementing a shared online repository for design documents and code, along with regular team meetings, can improve communication and transparency.

In summary, collaborative teamwork is an indispensable component of practical assignments. It not only enhances the likelihood of project success but also cultivates crucial professional skills necessary for future careers in the aerospace industry. Emphasizing collaborative learning environments and providing students with opportunities to develop teamwork skills are essential for preparing them to address the complex challenges of modern aerospace engineering.

Frequently Asked Questions Regarding Practical Applications

The following section addresses common inquiries related to the execution and value of practical applications within the field.

Question 1: What constitutes a suitable practical endeavor?

A suitable endeavor aligns with curriculum objectives, fosters application of theoretical knowledge, and cultivates problem-solving aptitude. Its scope allows for completion within allocated resources and timeframes, while posing sufficient challenges to promote learning.

Question 2: What resources are typically required?

Resource requirements vary depending on the nature. Access to computational tools, simulation software, fabrication facilities, and testing equipment is often essential. Material costs, faculty mentorship, and access to relevant literature also constitute important considerations.

Question 3: How is the performance evaluated?

Performance evaluation considers technical competence, adherence to design specifications, effective problem-solving, and project management skills. Written reports, oral presentations, and demonstration of working prototypes contribute to the overall assessment.

Question 4: What role do faculty advisors play?

Faculty advisors provide guidance, mentorship, and technical expertise throughout the project lifecycle. They assist in defining project scope, offer constructive feedback on design decisions, and ensure adherence to ethical and safety standards.

Question 5: How does collaboration influence outcomes?

Effective collaboration enhances outcomes by leveraging diverse skill sets, fostering knowledge sharing, and promoting efficient problem-solving. Clearly defined roles, open communication channels, and conflict resolution mechanisms are crucial for successful collaboration.

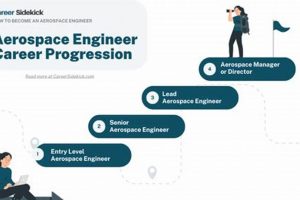

Question 6: How do these opportunities benefit future career prospects?

Practical applications significantly enhance future career prospects by providing hands-on experience, cultivating technical proficiency, and demonstrating the ability to apply theoretical knowledge to real-world problems. Employers value such experience, as it indicates preparedness for professional challenges.

In summary, thorough planning, resource management, effective collaboration, and faculty guidance are crucial for the success. These endeavors not only enrich academic understanding but also equip individuals with the skills and experience necessary to excel in the aerospace industry.

The subsequent section will offer concluding remarks on the significance of practical education in shaping the next generation of aerospace professionals.

Conclusion

The preceding discussion has illuminated the multifaceted nature of practical assignments, demonstrating their integral role in shaping future aerospace engineers. From design and analysis to fabrication and testing, these endeavors provide crucial hands-on experience, solidifying theoretical knowledge and fostering essential problem-solving skills. The significance of collaboration has also been emphasized, reflecting the team-oriented reality of the aerospace sector.

The commitment to providing relevant, challenging, and well-supported experiences remains paramount. As technology advances and the aerospace landscape evolves, continued investment in practical educational opportunities is essential to ensure that graduates are equipped to meet the challenges and drive innovation in this dynamic field. The future of aerospace engineering hinges on the ability to translate theoretical concepts into tangible realities, a capability fostered through rigorous practical education.