Individuals in this profession design, develop, test, and supervise the manufacturing of aircraft, spacecraft, satellites, and missiles. These professionals work with a variety of technologies, including propulsion systems, aerodynamics, and materials science, to create efficient and safe vehicles for both atmospheric and space environments. For example, an individual in this role might be involved in the design of a new commercial airliner, a satellite for communication purposes, or a rocket for space exploration.

The work of these experts is crucial for advancements in air travel, national defense, and space exploration. Their efforts contribute to improvements in fuel efficiency, safety standards, and the development of new technologies that benefit society. Historically, these professionals have played a pivotal role in shaping the aviation industry and driving innovation in space programs, leading to significant scientific discoveries and technological progress.

This overview provides a foundation for exploring the specific roles, responsibilities, and educational requirements associated with this engineering discipline. Subsequent sections will delve into the specialized areas of expertise, the necessary skills, and the career pathways available to individuals pursuing this challenging and rewarding field.

Essential Guidance for Aspiring Professionals

The following guidance is designed to assist individuals considering a career in this technically demanding field, focusing on key areas of preparation and professional development.

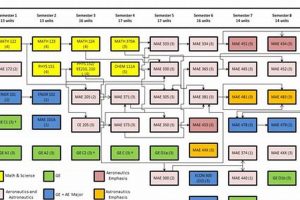

Tip 1: Emphasize a Strong Foundation in Mathematics and Physics: Success in this field necessitates a deep understanding of calculus, differential equations, linear algebra, fluid dynamics, thermodynamics, and advanced physics concepts. Students should prioritize these subjects in their academic curriculum.

Tip 2: Gain Practical Experience Through Internships: Internships with aerospace companies, government agencies, or research institutions provide invaluable hands-on experience. These opportunities allow students to apply theoretical knowledge to real-world problems and develop essential skills.

Tip 3: Develop Proficiency in Computer-Aided Design (CAD) and Engineering Software: Familiarity with industry-standard software such as CATIA, ANSYS, MATLAB, and SolidWorks is crucial for design, simulation, and analysis. Actively seek training and certification in these tools.

Tip 4: Focus on Specialization Within Aerospace Engineering: The field encompasses diverse areas, including aerodynamics, propulsion, structures, control systems, and avionics. Identifying a specific area of interest early on allows for targeted skill development and career planning.

Tip 5: Cultivate Strong Communication and Teamwork Skills: Aerospace projects are inherently collaborative. The ability to effectively communicate technical information, work within multidisciplinary teams, and present findings clearly is essential.

Tip 6: Pursue Advanced Education and Certifications: A master’s degree or doctorate can significantly enhance career prospects, particularly in research and development roles. Professional certifications, such as the Professional Engineer (PE) license, demonstrate competence and commitment.

Tip 7: Stay Abreast of Technological Advancements: The aerospace industry is constantly evolving. Continuous learning through professional development courses, industry conferences, and technical publications is vital to maintaining relevance and expertise.

By focusing on these key areas, prospective professionals can significantly increase their likelihood of success in this competitive and demanding field. A combination of strong academic preparation, practical experience, and continuous learning is the foundation for a fulfilling and impactful career.

This guidance provides a solid starting point for navigating the complexities of this engineering path. Further exploration of specific career paths and industry trends will contribute to a well-informed and successful career journey.

1. Design

Design is a foundational element in the realm of aerospace engineering, influencing every stage from conceptualization to production. It is not merely aesthetic; it is the iterative process of transforming requirements into tangible, functional, and safe aerospace vehicles and systems.

- Aerodynamic Configuration Design

This involves shaping aircraft and spacecraft to optimize airflow, minimize drag, and maximize lift. An example is the wing design of a commercial airliner, which balances efficiency, stability, and fuel consumption. Inefficient aerodynamic design can lead to increased fuel costs and compromised performance.

- Structural Design

Structural design ensures the integrity and durability of aerospace vehicles under extreme conditions. It involves selecting appropriate materials and designing load-bearing structures that can withstand stress, vibration, and temperature variations. The design of a spacecraft’s heat shield is crucial for protecting it during atmospheric re-entry. Flawed structural design can lead to catastrophic failure.

- Systems Integration Design

Aerospace vehicles are complex systems comprising numerous interconnected components, including propulsion, avionics, and life support. Systems integration design focuses on ensuring these systems function seamlessly and efficiently. For example, the integration of navigation and control systems in an unmanned aerial vehicle (UAV) is critical for autonomous operation. Poor systems integration can result in malfunctions and reduced operational effectiveness.

- Component Design

This involves the detailed design of individual parts such as engine turbines, landing gear, and control surfaces. It necessitates deep knowledge of material properties, manufacturing processes, and functional requirements. The design of a jet engine turbine blade, for example, requires intricate consideration of heat transfer, stress, and vibration. Inadequate component design can compromise the performance and reliability of the entire vehicle.

These facets of design collectively illustrate the central role it plays in aerospace engineering. Effective design optimizes performance, enhances safety, and drives innovation, contributing significantly to the advancement of aerospace technology and the success of aerospace endeavors. A systematic and thoughtful approach to each facet is paramount for achieving design excellence.

2. Development

Development, in the context of aerospace engineering, represents the critical transition from theoretical design to tangible reality. It encompasses the processes of prototyping, testing, and refining aerospace vehicles and systems. The activity requires a deep understanding of engineering principles, materials science, and manufacturing techniques. Development is not merely the physical construction of a design; it is an iterative process of validation and optimization. For example, the development of a new aircraft wing involves constructing scaled models, conducting wind tunnel tests to validate aerodynamic properties, and modifying the design based on test results. The developmental phase is essential to ensuring the vehicle or system meets performance specifications and safety standards. Without rigorous development, even the most brilliant designs may fail to achieve their intended functionality.

The effective development of aerospace technologies depends on close collaboration between design engineers, manufacturing specialists, and testing personnel. Each stage of development provides valuable feedback that can inform design modifications and manufacturing process improvements. Consider the development of reusable spacecraft, such as the Space Shuttle or more recent commercial ventures. Early prototypes underwent extensive flight testing to identify weaknesses in the thermal protection system, structural integrity, and control systems. This iterative process of testing and refinement enabled engineers to improve the reliability and performance of these complex vehicles. The ongoing development and testing of new rocket engine designs demonstrate the continuous need for refinement and optimization in the pursuit of increased efficiency and reduced emissions.

In conclusion, development is an indispensable component of aerospace engineering, transforming theoretical concepts into functional products through rigorous testing and iterative refinement. Its importance lies in ensuring that designs are not only theoretically sound but also practically viable and safe for operation. The challenges inherent in aerospace development, such as managing complexity, addressing safety concerns, and controlling costs, necessitate a multidisciplinary approach and a commitment to continuous improvement. Understanding the role of development is crucial to appreciating the full scope of this engineering field and its contribution to advancements in air and space travel.

3. Testing

Testing is a fundamental pillar in aerospace engineering, integral to validating designs, ensuring safety, and optimizing performance of aircraft, spacecraft, and related systems. It forms a critical link between theoretical design and practical application, providing empirical data essential for decision-making throughout the engineering lifecycle.

- Wind Tunnel Testing

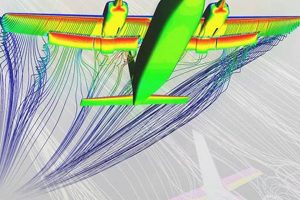

Wind tunnel testing involves subjecting scale models or full-size components to controlled airflow to simulate flight conditions. This allows engineers to measure aerodynamic forces, pressure distributions, and flow patterns, verifying design predictions and identifying potential issues such as turbulence or drag. For example, wind tunnel tests are routinely conducted on new aircraft wing designs to optimize lift and minimize drag, crucial for fuel efficiency. The data obtained directly impacts design modifications and safety considerations.

- Structural Testing

Structural testing assesses the ability of aerospace structures to withstand the loads and stresses encountered during operation. This includes static tests to determine strength under maximum loads and fatigue tests to evaluate long-term durability under cyclic loading. An example is the wing testing of a new aircraft where hydraulic actuators apply loads simulating flight maneuvers, allowing engineers to identify weak points and validate structural integrity. Failure during structural testing can lead to design revisions or material changes, ensuring the vehicle’s safety and reliability.

- Environmental Testing

Environmental testing exposes aerospace components and systems to extreme conditions, such as temperature variations, vacuum, radiation, and vibration, to simulate the harsh environments of flight or space. This helps identify potential failures or degradation due to environmental factors. For instance, satellites undergo extensive thermal vacuum testing to ensure they can operate reliably in the vacuum and extreme temperature fluctuations of space. Issues detected during environmental testing can lead to modifications in materials, coatings, or thermal management systems, ensuring the mission’s success.

- Flight Testing

Flight testing involves operating prototype or production aircraft in real-world flight conditions to evaluate performance, handling qualities, and system integration. This provides valuable data that cannot be obtained through ground-based testing alone. A recent example includes the flight testing of new autonomous drone delivery systems, where parameters such as stability, navigation accuracy, and obstacle avoidance are assessed. The results from flight testing inform design refinements and certification processes, validating the aircraft’s capabilities and safety for operational use.

These facets of testing underscore its vital role in aerospace engineering. From validating aerodynamic designs to ensuring structural integrity and assessing environmental resilience, testing provides crucial feedback that directly influences the design, development, and certification of aerospace vehicles and systems. Testing ensures the safety, reliability, and performance of aircraft and spacecraft operating in demanding and unforgiving environments.

4. Manufacturing

Manufacturing is an indispensable function within aerospace engineering, representing the physical realization of designs into tangible aircraft, spacecraft, and associated systems. The role of professionals in this field directly impacts the efficiency, cost-effectiveness, and quality of aerospace products. Their expertise ensures that theoretical designs are translated into functional, reliable, and safe products that meet stringent performance requirements.

- Materials Selection and Processing

Professionals in manufacturing determine the appropriate materials and processing techniques required to construct aerospace components. This includes selecting lightweight yet strong materials such as aluminum alloys, titanium, and composites, and implementing manufacturing processes like machining, casting, forging, and additive manufacturing. For example, the selection of carbon fiber composites for aircraft wings requires expertise in layup techniques, curing processes, and non-destructive testing to ensure structural integrity. Inappropriate material selection or processing can compromise structural integrity and increase the risk of failure.

- Precision Manufacturing and Assembly

Aerospace manufacturing demands extremely high levels of precision and accuracy. Engineers are responsible for designing manufacturing processes, tooling, and fixtures that can achieve tight tolerances and ensure proper assembly of complex components. The manufacturing of jet engine turbine blades, for instance, requires intricate machining processes and stringent quality control measures to meet aerodynamic performance requirements. Errors in manufacturing or assembly can significantly reduce performance and increase the risk of malfunctions.

- Quality Control and Assurance

Implementing rigorous quality control measures is crucial to ensuring the reliability and safety of aerospace products. Aerospace personnel develop and implement quality management systems, conduct inspections and tests, and analyze data to identify and correct manufacturing defects. Radiographic inspection of welds in rocket engine combustion chambers, for example, is a standard practice to detect porosity or cracks that could lead to catastrophic failure. Lax quality control can lead to safety hazards and compromised product performance.

- Automation and Robotics

The integration of automation and robotics is becoming increasingly prevalent in aerospace manufacturing, driven by the need to improve efficiency, reduce costs, and enhance quality. Aerospace experts are involved in designing and implementing automated manufacturing systems, programming robots to perform repetitive tasks, and developing advanced manufacturing techniques. The use of robotic arms for the precision drilling of aircraft fuselage panels reduces human error and increases production rates. Failure to implement automation effectively can result in higher production costs and lower throughput.

The various facets of manufacturing underscore the critical role these specialists play in the aerospace industry. From selecting appropriate materials to implementing quality control measures and embracing automation, manufacturing expertise is essential for translating theoretical designs into practical, reliable, and safe aerospace products. Addressing the challenges associated with manufacturing, such as managing complexity, controlling costs, and ensuring quality, requires a multidisciplinary approach and a commitment to continuous improvement. An understanding of manufacturing processes is crucial to appreciating the full scope of this engineering field and its contribution to advancements in air and space travel.

5. Analysis

Analysis forms a cornerstone of activities undertaken by professionals in the aeronautical and astronautical fields. This multifaceted process encompasses a broad range of techniques used to understand, predict, and optimize the performance and behavior of aerospace vehicles and systems. Without thorough analysis, designs remain theoretical constructs lacking the validation necessary for safe and effective implementation. The work conducted in this field is not merely a component; it is a prerequisite for success, ensuring that aerospace endeavors meet stringent performance and safety criteria. For example, finite element analysis (FEA) is routinely employed to assess the structural integrity of aircraft wings under various load conditions, identifying potential stress concentrations that could lead to failure. The results of such analyses directly inform design modifications and material selections, mitigating risks and enhancing performance.

Further examination reveals the practical significance of understanding analytical methods in aerospace engineering. Computational fluid dynamics (CFD) simulations are used to model airflow around aircraft, optimizing aerodynamic efficiency and reducing drag. These simulations, based on complex mathematical models, allow engineers to predict and refine aerodynamic performance before physical prototypes are even constructed. Similarly, propulsion system analysis involves thermodynamic modeling and combustion simulations to optimize engine performance and reduce emissions. The iterative process of analysis and design improvement results in vehicles that are more efficient, reliable, and environmentally friendly. The Space Shuttle program, for instance, relied heavily on sophisticated trajectory analysis to ensure safe and accurate orbital maneuvers, demonstrating the pivotal role of this process in complex aerospace missions.

In summary, analytical methods are indispensable to professionals within this engineering domain, providing the foundation for informed decision-making and innovation. The challenges inherent in the field, such as managing complexity and addressing safety concerns, necessitate a strong analytical skillset. The future of aerospace engineering hinges on continued advancements in analytical techniques and the ability of aerospace professionals to effectively apply these tools to design and optimize the next generation of air and space vehicles. These are not theoretical exercises; they are practical necessities for ensuring the safety and success of all aerospace endeavors.

6. Research

Research forms the bedrock of progress in the field, fueling innovation and enabling the development of advanced technologies. It is an essential activity for individuals in this profession, driving the evolution of aircraft, spacecraft, and related systems. Without robust research efforts, the field would stagnate, unable to address emerging challenges or capitalize on new opportunities.

- Aerodynamics and Fluid Dynamics Research

This area focuses on understanding and manipulating the flow of air around aircraft and spacecraft to improve performance and efficiency. Research in computational fluid dynamics (CFD) and experimental aerodynamics leads to innovative wing designs, reduced drag, and enhanced stability. For example, the development of winglets on commercial airliners stems from extensive research in aerodynamics, significantly improving fuel efficiency and reducing carbon emissions. These advancements demonstrate how research directly impacts the operational capabilities and environmental footprint of aerospace vehicles.

- Materials Science Research

Materials science research explores the development of novel materials with enhanced strength, reduced weight, and improved resistance to extreme temperatures and pressures. This research is crucial for creating lighter and more durable aircraft and spacecraft, enabling higher performance and increased payload capacity. The development of carbon fiber composites, for instance, has revolutionized aircraft construction, allowing for lighter and stronger airframes. This research directly influences the structural integrity and operational life of aerospace vehicles.

- Propulsion Systems Research

Research in propulsion systems aims to develop more efficient, reliable, and environmentally friendly engines for aircraft and spacecraft. This includes exploring advanced combustion techniques, alternative fuels, and novel engine designs such as scramjets and electric propulsion systems. The development of more fuel-efficient jet engines reduces operating costs and emissions, while research into electric propulsion systems enables new possibilities for space exploration. These advancements demonstrate how research drives improvements in both performance and sustainability.

- Autonomous Systems and Robotics Research

This area focuses on developing autonomous systems and robotics for aerospace applications, including unmanned aerial vehicles (UAVs), autonomous spacecraft, and robotic systems for manufacturing and maintenance. Research in artificial intelligence, sensor technologies, and control systems enables the creation of more capable and versatile aerospace systems. The development of autonomous drones for delivery and surveillance applications, as well as robotic systems for assembling spacecraft in orbit, highlights the transformative potential of this research. The research is shaping the future of air and space travel.

These facets of research collectively demonstrate its central role in advancing the field. From improving aerodynamic efficiency to developing new materials and propulsion systems, research drives innovation and enables individuals in the profession to push the boundaries of what is possible in air and space travel. The ongoing commitment to research is essential for ensuring the continued progress and competitiveness of the aerospace industry.

Frequently Asked Questions

This section addresses common inquiries regarding the field, providing clarity on aspects of education, career paths, and industry expectations.

Question 1: What educational qualifications are essential for aspiring individuals?

A bachelor’s degree in aerospace engineering or a closely related field, such as mechanical engineering, is typically the minimum requirement. A strong foundation in mathematics, physics, and computer science is crucial. Advanced roles often necessitate a master’s degree or doctorate, especially in research-oriented positions.

Question 2: What are the primary differences between aeronautical and astronautical engineering?

Aeronautical engineering focuses on the design and development of aircraft that operate within Earth’s atmosphere. Astronautical engineering, conversely, centers on spacecraft, satellites, and other vehicles designed for operation in space.

Question 3: Which specific skills are highly valued by employers?

Employers seek candidates with strong analytical and problem-solving skills, proficiency in computer-aided design (CAD) software, and a thorough understanding of aerospace principles. Effective communication, teamwork, and project management abilities are also highly desirable.

Question 4: What are the potential career paths available in this field?

Career opportunities span diverse sectors, including commercial aviation, defense, space exploration, and research. Common roles include design engineer, test engineer, systems engineer, and project manager. Government agencies and private aerospace companies offer varied employment prospects.

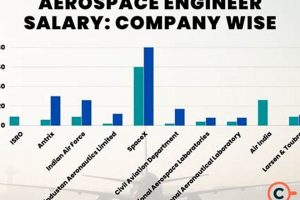

Question 5: What is the expected salary range for professionals in this field?

Salaries vary based on experience, education, and location. Entry-level positions typically offer competitive salaries, with significant earning potential for experienced professionals and those in specialized roles.

Question 6: What are the key challenges facing the aerospace industry today?

The industry faces numerous challenges, including reducing carbon emissions, improving fuel efficiency, developing sustainable propulsion systems, and ensuring the safety and reliability of increasingly complex aerospace systems.

This overview provides a foundation for understanding the breadth and depth of aerospace engineering. Further research and exploration will enhance comprehension of this dynamic field.

Transition to the next article section, which will delve into emerging trends in the field.

Conclusion

This article has explored what constitutes an aerospace engineer, emphasizing the diverse roles, responsibilities, and skills essential for success in this field. The comprehensive overview has covered critical aspects such as design, development, testing, manufacturing, analysis, and research, underscoring the multifaceted nature of the profession.

The continued advancements in aviation and space exploration rely on the expertise and dedication of professionals working in this domain. Their contributions are vital for ensuring the safety, efficiency, and innovation that drive progress in air and space travel. The pursuit of knowledge and excellence in this field will shape the future of aerospace technology and exploration.