This field represents a specialized branch of engineering focused on the design, development, testing, and production of aircraft, spacecraft, and related systems within a specific geographical locale. This specialized focus allows for the cultivation of expertise tailored to regional resources, infrastructure, and market demands, fostering innovation in areas such as propulsion systems, aerodynamics, materials science, and avionics specific to that area.

A concentration within this discipline provides several key advantages. It fosters local economic growth by creating high-skilled jobs and attracting investment in research and development. Furthermore, it contributes to national security by enabling the development of cutting-edge aerospace technologies. Historically, centers of expertise in this area have played a critical role in advancing aviation and space exploration.

The subsequent sections will delve into specific aspects of this engineering focus, examining its role in advancing space technologies, addressing aviation challenges, and promoting technological advancement and regional prosperity.

Guidance within the Field

The following points provide valuable insight for those involved in or seeking to enter the specialized field. They underscore critical areas for success and contribute to the ongoing advancement of the industry.

Tip 1: Emphasize System Integration Skills: A comprehensive understanding of how various components interact within aerospace systems is paramount. This includes proficiency in areas such as avionics, propulsion, and structural mechanics. Examples include expertise in modeling system behavior or troubleshooting integrated platform issues.

Tip 2: Prioritize Materials Science Knowledge: Aerospace applications demand advanced materials with exceptional strength-to-weight ratios and resistance to extreme conditions. Develop a strong foundation in metallurgy, composites, and nanomaterials to contribute to innovative designs. An example of this would be the development of new lightweight alloys with enhanced heat resistance for hypersonic aircraft.

Tip 3: Cultivate Expertise in Simulation and Modeling: Computer-aided engineering (CAE) tools are essential for designing, analyzing, and optimizing aerospace systems. Gain proficiency in finite element analysis (FEA), computational fluid dynamics (CFD), and other simulation techniques. Use simulation tools to predict aerodynamic performance or to analyze structural integrity under stress.

Tip 4: Foster Collaboration and Communication Skills: Aerospace projects typically involve multidisciplinary teams working on complex tasks. Effective communication and collaboration are crucial for ensuring seamless integration and project success. Work effectively with other disciplines and stakeholders.

Tip 5: Pursue Continuous Learning and Professional Development: The aerospace industry is constantly evolving, with new technologies and innovations emerging regularly. Stay abreast of the latest advancements through conferences, workshops, and continuing education programs.

Tip 6: Engage in Research and Development: Contributing to research and development efforts is vital for advancing the field and maintaining a competitive edge. Participate in research projects, publish papers, and collaborate with universities and research institutions. An example is working on projects that improve fuel efficiency or enhance aircraft safety.

Applying these points will enhance one’s contribution and benefit the overall specialized field.

These points provide a foundation for navigating the complexities and opportunities within this focused domain. The next stage will transition to address its future development and the potential challenges that lie ahead.

1. Regional Resource Optimization

Within the context of the specialized field, the strategic utilization of locally available resources constitutes a fundamental pillar for sustainable development and competitive advantage. This optimization process necessitates a comprehensive evaluation of the region’s assets and their integration into aerospace activities.

- Material Sourcing and Processing

The proximity to specific raw materials or processing facilities significantly reduces transportation costs and lead times. If a region possesses deposits of aluminum, titanium, or carbon fiber composites, establishing local processing capabilities can directly support aerospace manufacturing. Integration of existing industries that may supply raw materials.

- Infrastructure Leveraging

Existing infrastructure, such as airports, industrial parks, and transportation networks, presents opportunities for cost-effective expansion and development of aerospace facilities. Adapting existing facilities minimizes initial capital investment and facilitates quicker project deployment, while leveraging transportation networks ensures efficient logistics for component transport and distribution.

- Energy Resource Utilization

The availability and cost of energy resources directly impact the operational expenses of aerospace manufacturing and testing facilities. Regions with access to renewable energy sources, such as solar or wind power, can reduce their carbon footprint and enhance long-term economic sustainability for energy-intensive aerospace operations.

- Workforce Development Alignment

Aligning educational programs and vocational training with the specific needs of the regional aerospace sector ensures a skilled workforce capable of meeting current and future demands. Tailored training programs, apprenticeships, and partnerships with local educational institutions enhance workforce competency and reduce recruitment costs.

The strategic alignment of these resources is essential for fostering a thriving and self-sufficient aerospace ecosystem. By effectively leveraging locally available assets, this engineering segment within a specified region can enhance its competitiveness, promote innovation, and contribute to sustained economic growth.

2. Skilled Workforce Development

A strategically developed and highly skilled workforce is foundational to the advancement and sustained success of this focused engineering sector. Workforce competence dictates the capacity for innovation, precision manufacturing, and the effective management of complex systems inherent in the aerospace domain.

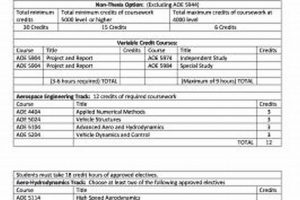

- Targeted Educational Programs

The establishment of specialized educational programs at local universities and vocational schools is critical. These programs should focus on aerospace-specific engineering disciplines, including aerodynamics, propulsion systems, materials science, and avionics. An example would be a Bachelor of Science degree program in Aerospace Engineering with a concentration in aircraft design or a specialized vocational training program focused on precision machining of aerospace components. These initiatives ensure a steady supply of qualified graduates and technicians.

- Industry-Academia Partnerships

Collaborative partnerships between aerospace companies and academic institutions facilitate the transfer of knowledge and provide students with practical, hands-on experience. Internship programs, research collaborations, and guest lectures by industry experts enhance students’ understanding of real-world challenges and prepare them for future roles. For example, a local aerospace manufacturer might partner with a university to conduct research on advanced composite materials or to develop new manufacturing processes.

- Apprenticeship and Vocational Training

Apprenticeship programs offer a structured pathway for individuals to acquire specialized skills through on-the-job training under the guidance of experienced professionals. Vocational training programs provide targeted instruction in areas such as aircraft maintenance, avionics repair, and precision manufacturing. These programs are particularly valuable for developing a skilled workforce capable of meeting the immediate needs of the aerospace industry.

- Continuous Professional Development

The aerospace industry is characterized by rapid technological advancements, necessitating ongoing professional development for engineers and technicians. Continuing education courses, workshops, and conferences enable professionals to stay abreast of the latest innovations and best practices. Certifications in specialized areas, such as project management, quality control, and regulatory compliance, enhance their expertise and career prospects.

The synergistic effect of these facets fosters a competent and adaptable workforce, enabling the region to excel in aerospace engineering endeavors. This commitment to skilled workforce development is essential for driving innovation, attracting investment, and ensuring the long-term competitiveness of this specialized field.

3. Local supply chain integration

Effective integration of local suppliers into the aerospace engineering supply chain is a critical factor determining efficiency, responsiveness, and economic benefit within a specified region. By prioritizing regional partnerships, the aerospace sector can mitigate risks associated with global sourcing, reduce lead times, and stimulate economic growth within the local economy.

- Reduced Lead Times and Transportation Costs

Engaging with local suppliers shortens supply chains, reducing both lead times and transportation expenses. Proximity enables faster delivery of components, decreasing inventory holding costs and improving responsiveness to changing production demands. Example: A locally sourced supplier of precision-machined parts can deliver components within days, compared to weeks or months from overseas suppliers, improving production agility.

- Enhanced Quality Control and Communication

Closer proximity facilitates direct communication and collaboration between aerospace manufacturers and their suppliers, improving quality control and problem resolution. Regular site visits and face-to-face meetings enable proactive identification and mitigation of potential quality issues. Example: Local suppliers can participate in joint design reviews, providing feedback on manufacturability and identifying potential improvements early in the product development cycle.

- Economic Development and Job Creation

Prioritizing local suppliers stimulates economic growth and creates jobs within the region. Increased demand for goods and services from local businesses generates additional revenue and employment opportunities, benefiting the entire community. Example: An aerospace manufacturer’s decision to source its wiring harnesses from a local company can lead to the creation of dozens of skilled jobs in the region.

- Agility and Resilience

Supply chain localization enhances operational agility and resilience by reducing dependence on distant or politically unstable regions. Diversification of local supply alternatives mitigates risks associated with global disruptions, such as natural disasters, geopolitical instability, or trade disputes. Example: During a global pandemic, a regional aerospace manufacturer with a localized supply chain can maintain production more effectively than a competitor relying on international suppliers.

The integration of local suppliers strengthens the aerospace engineering base by fostering innovation, enhancing competitiveness, and contributing to regional prosperity. The benefits derived from this approach extend beyond individual companies, creating a more robust and sustainable aerospace ecosystem.

4. Specialized testing infrastructure

In the context of Windsor’s aerospace engineering sector, specialized testing infrastructure plays a crucial role in verifying the performance, reliability, and safety of aerospace components and systems. Its presence facilitates innovation, ensures regulatory compliance, and ultimately supports the competitiveness of local industries.

- Environmental Simulation Chambers

These chambers replicate the extreme conditions encountered during flight, including temperature variations, pressure changes, humidity, and exposure to radiation. Simulating these environments allows engineers to assess the durability and functionality of aerospace components under realistic operating conditions. For example, a component intended for use in a satellite might be subjected to vacuum conditions and extreme temperature fluctuations to ensure it can withstand the harsh environment of space. This ensures functionality and prevents premature failure in orbit, preserving the mission.

- Structural Testing Facilities

Structural testing facilities are equipped with specialized equipment for applying static and dynamic loads to aerospace structures, such as wings, fuselages, and landing gear. These tests verify the structural integrity of these components under various stress conditions, including those encountered during takeoff, landing, and in-flight maneuvers. Example: A full-scale wing section might be subjected to cyclical loading to simulate the stresses accumulated over thousands of flight hours, identifying potential fatigue issues before they occur in service, greatly enhancing safety.

- Propulsion Testing Capabilities

Testing propulsion systems, such as jet engines and rocket motors, requires specialized facilities with the capacity to handle high temperatures, pressures, and exhaust gases. These facilities are used to measure thrust, fuel consumption, and emissions, as well as to evaluate the performance and durability of engine components. Example: A test cell equipped with sophisticated instrumentation can measure the thrust produced by a jet engine under different operating conditions, allowing engineers to optimize its performance and reduce fuel consumption, for economic and environmental reasons.

- Non-Destructive Testing (NDT) Equipment

Non-destructive testing techniques, such as ultrasonic testing, radiography, and magnetic particle inspection, are used to detect flaws and defects in aerospace components without damaging them. These techniques are essential for ensuring the quality and reliability of critical parts, such as turbine blades and structural welds. Example: Ultrasonic testing can be used to detect subsurface cracks in a turbine blade without requiring disassembly or causing damage, thereby extending service life and reducing maintenance costs.

The availability and sophistication of specialized testing infrastructure directly impacts the ability of Windsor’s aerospace engineering sector to develop innovative and competitive products. These resources enable local companies to conduct rigorous testing, validate designs, and meet stringent regulatory requirements, solidifying their position in the global aerospace market.

5. Innovation-driven research

Innovation-driven research forms the bedrock of progress within Windsor’s aerospace engineering sector. It fosters the development of novel technologies, processes, and solutions that are vital for maintaining competitiveness in an increasingly dynamic global market. Investment in and cultivation of research capabilities translate directly into enhanced product performance, reduced costs, and the creation of high-value jobs within the region.

- Advanced Materials Development

Research into novel materials, such as lightweight composites, high-temperature alloys, and self-healing materials, drives significant improvements in aircraft performance and fuel efficiency. For example, the development of carbon fiber reinforced polymers has enabled the construction of lighter aircraft structures, reducing fuel consumption and increasing payload capacity. This research leads to reduced operational costs and lessened environmental impact.

- Autonomous Systems and Robotics

Exploration of autonomous systems and robotics technologies contributes to enhanced aircraft safety, improved operational efficiency, and reduced labor costs. For example, research into autonomous flight control systems enables the development of unmanned aerial vehicles (UAVs) for various applications, including surveillance, inspection, and cargo delivery. In Windsor, this focus is particularly relevant for its proximity to the automotive sector, where similar technologies are under development.

- Advanced Manufacturing Techniques

Research into advanced manufacturing processes, such as additive manufacturing (3D printing) and precision machining, enables the production of complex aerospace components with greater precision, efficiency, and cost-effectiveness. For example, 3D printing allows for the creation of customized parts with optimized geometries, reducing material waste and improving overall performance. Investment in this research stimulates manufacturing innovation and increases the competitiveness of Windsor’s aerospace sector.

- Sustainable Aviation Technologies

Research aimed at developing sustainable aviation technologies addresses growing environmental concerns and reduces the carbon footprint of the aerospace industry. Examples include the development of electric and hybrid-electric propulsion systems, alternative fuels, and aerodynamic improvements. Government-supported research programs incentivize these technologies and contribute to more environmentally responsible aerospace practices.

These research-driven advancements collectively strengthen Windsor’s aerospace engineering industry. By prioritizing innovation and investing in research capabilities, the region can solidify its position as a hub for aerospace technology development, attracting investment, creating high-skilled jobs, and contributing to a more sustainable future for aviation.

6. Regulatory compliance adherence

Adherence to stringent regulatory standards is paramount within the field of aerospace engineering, particularly within a defined geographical area. This adherence not only ensures the safety and reliability of aerospace products and services but also governs the operational practices of organizations involved in their design, manufacture, and maintenance.

- Federal Aviation Regulations (FARs) Compliance

Compliance with FARs, as administered by the relevant aviation authority, is mandatory for all aspects of aircraft design, production, and operation. This encompasses airworthiness standards, maintenance procedures, and operational guidelines. For example, an aerospace engineering firm in the specified area must demonstrate compliance with FAR Part 25 concerning airworthiness standards for transport category airplanes to obtain type certification for a newly designed aircraft. Non-compliance can lead to grounding of aircraft, fines, or revocation of operating certificates.

- International Standards Organization (ISO) Certification

ISO certifications, such as ISO 9001 and AS9100 (specific to the aerospace industry), demonstrate a commitment to quality management systems and adherence to internationally recognized standards. These certifications provide assurance that an organization has established processes and procedures to consistently deliver products and services that meet customer and regulatory requirements. Attaining AS9100 certification requires rigorous audits and documentation, ensuring that all processes, from design to manufacturing, are controlled and continuously improved. This builds customer confidence and facilitates access to global markets.

- Environmental Regulations Compliance

Aerospace activities are subject to environmental regulations concerning emissions, noise pollution, and waste management. Compliance with these regulations necessitates the implementation of environmentally friendly technologies and practices. For instance, aerospace manufacturers must adhere to regulations governing the disposal of hazardous materials used in aircraft production. Failure to comply with environmental regulations can result in significant fines and reputational damage.

- Export Control Regulations Adherence

Export control regulations, such as the International Traffic in Arms Regulations (ITAR), govern the export of aerospace technologies and components to foreign countries. Compliance with these regulations requires thorough understanding of export licensing requirements and restrictions. Aerospace companies involved in the development or manufacture of sensitive technologies must obtain export licenses before transferring these technologies to foreign entities. Violation of export control regulations can result in severe penalties, including fines, imprisonment, and loss of export privileges.

The facets outlined are integral to the operational and ethical standing of any aerospace engineering entity. Strict adherence to these regulatory frameworks is not merely a legal obligation but a fundamental aspect of ensuring safety, maintaining quality, and promoting sustainable practices within the aerospace sector.

7. Economic impact assessment

The systematic evaluation of the economic consequences associated with Windsor’s aerospace engineering sector is crucial for informed decision-making and strategic planning. These assessments, often quantitative in nature, analyze the industry’s contribution to regional employment, gross domestic product (GDP), tax revenues, and related economic indicators. A positive economic impact assessment can serve as justification for public investment in aerospace infrastructure, workforce development programs, and research and development initiatives. Conversely, a negative assessment might prompt adjustments to policies or strategies aimed at mitigating adverse economic effects. For example, if a proposed aerospace manufacturing facility is projected to generate substantial employment opportunities and tax revenues, the local government may be more inclined to offer tax incentives or infrastructure improvements to attract the investment.

Economic impact assessments also play a pivotal role in evaluating the effectiveness of existing aerospace-related programs and policies. By quantifying the economic benefits resulting from these interventions, policymakers can determine whether resources are being allocated efficiently and whether adjustments are needed to maximize economic returns. For instance, an assessment of a local aerospace training program might reveal that graduates are securing high-paying jobs in the industry, leading to increased earnings and tax revenues. This positive outcome would support continued funding for the program and potentially expansion to other regions. A real-world example is the assessment of aerospace clusters in regions like Toulouse, France, where meticulous economic analyses demonstrated a significant multiplier effect, justifying further investments in aerospace education, research, and infrastructure.

In summary, economic impact assessments serve as a critical feedback loop for Windsor’s aerospace engineering efforts. They provide a data-driven basis for attracting investment, optimizing resource allocation, and demonstrating the value of the industry to the broader community. Effectively leveraging these assessments enables stakeholders to make well-informed decisions that promote the long-term growth and sustainability of the aerospace sector within the Windsor region and beyond.

Frequently Asked Questions

The following questions address common inquiries regarding aerospace engineering, particularly within the context of a specific location. These answers aim to provide clear and concise information for those seeking a deeper understanding of the field.

Question 1: What specific areas of aerospace engineering are typically emphasized?

The focus often encompasses aircraft design, propulsion systems, materials science, avionics, and space systems. Specialization may vary depending on regional capabilities and market demands. For instance, composite material research may be prioritized if the local industry has a strong background in advanced manufacturing.

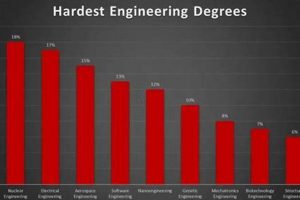

Question 2: How does this focused approach differ from general aerospace engineering programs?

Concentrated efforts allow for the development of specialized expertise and the cultivation of regional advantages. This may involve closer collaboration with local industries and a curriculum tailored to address regional needs and resources.

Question 3: What career opportunities are available to graduates specializing in this field?

Potential career paths include roles in aircraft design and manufacturing, space systems development, research and development, regulatory agencies, and related consulting services. Graduates may find employment with local aerospace companies, government agencies, or research institutions.

Question 4: What are the key skills and qualifications sought by employers?

Employers typically seek candidates with strong analytical and problem-solving skills, a solid foundation in mathematics and physics, and expertise in relevant software tools and engineering principles. Experience through internships or research projects is also highly valued.

Question 5: How does one contribute to innovation in this specific engineering sector?

Contributing to innovation involves staying abreast of the latest technological advancements, engaging in research and development projects, collaborating with industry partners, and seeking opportunities to apply new technologies to address existing challenges.

Question 6: What are the major challenges facing the aerospace industry?

The aerospace industry faces ongoing challenges related to sustainability, safety, cost reduction, and technological advancement. Addressing these challenges requires collaborative efforts from engineers, researchers, policymakers, and industry stakeholders.

The insights provided offer a foundational understanding. Further exploration into this complex domain will undoubtedly reveal more granular and specific information.

The next section will address the challenges and future outlook for engineering applications in this arena.

Conclusion

This examination of Windsor aerospace engineering reveals a specialized field with significant regional economic and technological implications. Emphasis has been placed on the importance of regional resource optimization, skilled workforce development, and robust regulatory compliance. Furthermore, innovation-driven research and strategic supply chain integration were highlighted as critical components for sustained success.

Continued strategic investment in these key areas will be essential to ensure that Windsor aerospace engineering remains a vital contributor to both the local and broader aerospace landscape. Future growth will depend on proactively addressing the challenges of sustainability, safety, and global competition, ensuring a resilient and innovative future for this specialized engineering sector.

![Best Colleges with Aerospace Engineering Major [Rankings] Innovating the Future of Flight with Reliable Aviation Solutions Best Colleges with Aerospace Engineering Major [Rankings] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-497-300x200.jpg)

![Top Illinois Aerospace Engineering Colleges [Guide] Innovating the Future of Flight with Reliable Aviation Solutions Top Illinois Aerospace Engineering Colleges [Guide] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-495-300x200.jpg)